You might have heard of DTF film before. In daily life, products made of DTF film can be found in many places, including shopping malls and your home. You can consider it as a kind of transfer paper that can work on almost all kinds of textile fabrics. If you often use sublimation paper, we hope this article can help you to try this brand-new kind of transfer product. We are sure you will regret not knowing about the new product sooner after learning about it. We believe that the DTF film will bring you the best experience you have ever had.

What is DTF Film?

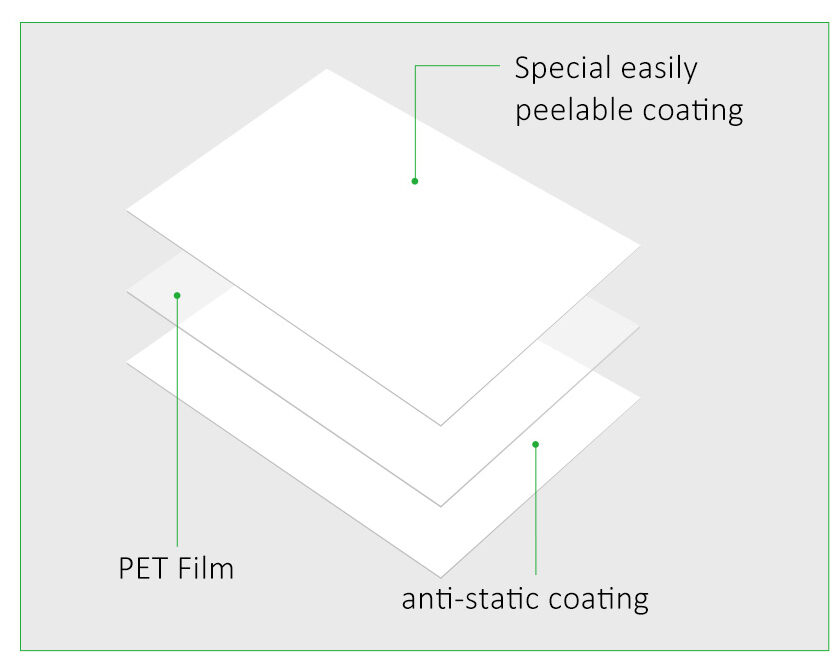

DTF film is a brand-new transfer operation that can transfer on almost all textile fabrics. As we can see in the image above, there are three parts to DTF film. They are special easily peel-able coating, PET film, and anti-static coating. The special easily peelable coating is used to protect the PET film from scratch. The PET film is the substrate. And as its name implies, the anti-static coating is used to prevent static electricity.

Application of DTF Film

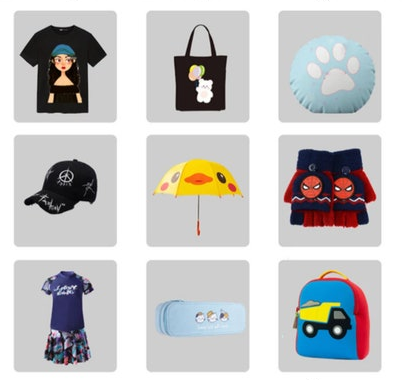

DTF film can be used in many fields. Almost all textile fabrics can be transferred by DTF film. It can be used on all kinds of dark and light color canvas, cotton T-shirts, row undershirts, denim, nylon, etc. This makes the manufacturers more choices in fabrics. They will not be limited by fabrics or must buy special paper to heat transfer different kinds of fabrics. As a result, DTF saves the manufacturers’ time and money to a large extent.

Why Should We Store the DTF Film Properly?

Although DTF film is not normal paper and has a protective coating, it still needs to be stored properly. The water vapor in the air will percolate into the PET film. This may make the film crimped and humid. Then the printing effect during the process of transferring will be broken. This will have a huge impact and loss on the production of products. The production efficiency also becomes unstable because of the quality of PET film. This is a very serious problem for the manufacturers. As a result, it is of great importance to store the DTF film in the proper ways. You may spend a little money and time on it, but it’s definitely worth it.

5 Tips on Storage of DTF Film

To help you learn more about proper ways of storing DTF film, we list these 5 tips below. We hope these tips can help you a lot in your production, and save you money and time to a large extent. By the way, do not forget to keep the other DTF products like DTF powder in the same storage space, too.

●Proper Temperature and Humidity

As we all know, the proper temperature and humidity are necessary for the storage of anything. As a result, as a kind of paper, the DTF film also has a strict standard for its storage. This special transfer film may be crimped because of the inappropriate temperature and humidity in summer or winter. 70°F / 21 °C and 50% relative humidity is perfect. Once the film becomes wrinkled, it will be irreversible. So is your time and money. You need to buy a new DTF film again and wait for a long time.

●Sealed Package

In addition to the temperature and humidity mentioned above, sealed packaging can also help you store DTF film better. The sealed package provides a certain degree of isolation from the DTF film and air. The package is also kept as dry as possible. This prevents the shortening of the shelf life of DTF films.

●Protect Against Direct Sunlight

Direct sunlight is one of the common problems faced by the storage of items. The best way is to store the products in a back shade and light-free environment. Direct sunlight will cause the products to fade or yellow gradually. The heat caused by direct sunlight can also cause DTF film to crease to varying degrees.

●Storage Space

Most of the unusual warehouses are built of concrete. But as a space for storing paper, we prefer to use special racks and pallets. When the weather changes, the concrete comes in contact with the heat and condenses water vapor, which has a direct impact on the storage of DTF film. At the same time, the uneven quality of concrete floor slabs can make them inherently less resistant to permeation. If conditions allow, please equip the warehouse with a dehumidifier.

●Avoid High-Temperature Environments

100 °F / 38 °C or more must be avoided in the storage space. High temperatures will not only make the paper too dry and distorted but may also cause it to burn. If not dealt with in a timely manner, the consequences of such would be devastating. In summary, it is necessary to have temperature and humidity detectors in the warehouse.

Conclusion

For merchants, storage seems to be the most common part of the process. But in reality, proper storage can bring you manageable loss minimization. When you put thought into storage, you get the longest life out of your raw materials. All it takes is an airtight warehouse, a thermometer, and a humidity detector, and you’re on your way to doing your best. Why not go ahead with it? Don’t overlook this small detail, and you won’t regret the small expense.

Thank you for reading this article. We also hope this article will help your DTF career more. To learn more about DTF, you can read this article, What is DTF Printing?. If you have any questions related to DTF, please feel free to contact us. We are always ready to provide you with the best consulting services. Of course, our DTF one-stop solution can also provide you with the best buying experience.