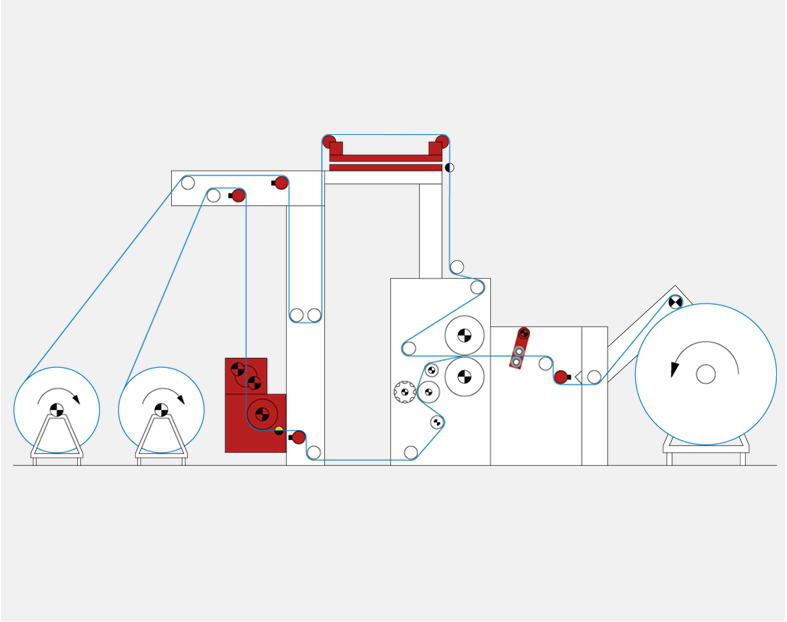

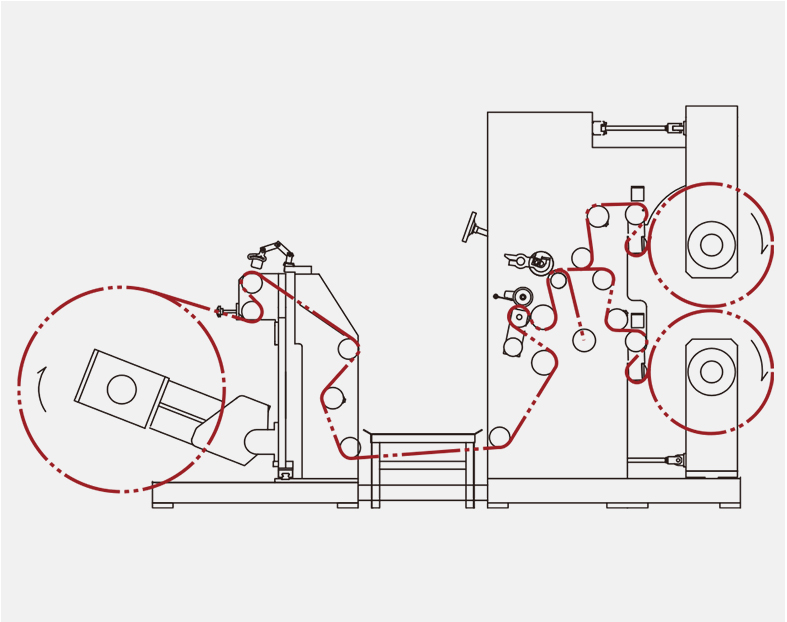

A-SUB® has 4 rewinding machines, 3 vertical

and horizontal cutting machines, and 2 fine cutting machines to meet the needs of different dimensional tolerance.

Quality Inspection Standard:

1. Length and width tolerance: ±1mm, diagonal tolerance ±0.5mm

2. Long side, wide side ≤ 5mm, slight waves ≤ 3, no twisted curls are allowed

3. Paper direction must be consistent