Brief Introduction to Desktop DTF

DTF is a kind of operation that can heat transfer the pattern to the substrates through the powder. The transferred effects are very pretty and vivid. Nowadays, there are many people who want to try DTF because of its popularity. What’s more, it has no limitation in the fabrics and original color of the substrates. If you use other kinds of operations, you must have difficulties in choosing the fabric and original color of the substrates. But, you can use DTF on the substrates of any fabric and original color without worries.

What Do We Need to Do Desktop DTF?

Desktop DTF is different from DTF’s one-stop solution. Most small manufacturers use desktop DTF or try it in the beginning. Desktop DTF is usually used in the office or small manufacturing enterprise. It doesn’t need to use special machines like a powder shaker. The desktop DTF is easy to try than the one-stop solution. The machines we need are a modified printer, an oven, and a heat press.

●DTF Film

DTF film is made of PET. There are two kinds of DTF film, single-sided and double-sided. Normally, DTF film has diverse sizes to transfer like its sublimation paper. When it is printed, the image area will be sticky. This area is used to stick the powder. As a result, the DTF film doesn’t need to use a cutting machine to cut its image after printing. It will save a lot of time during the process of production.

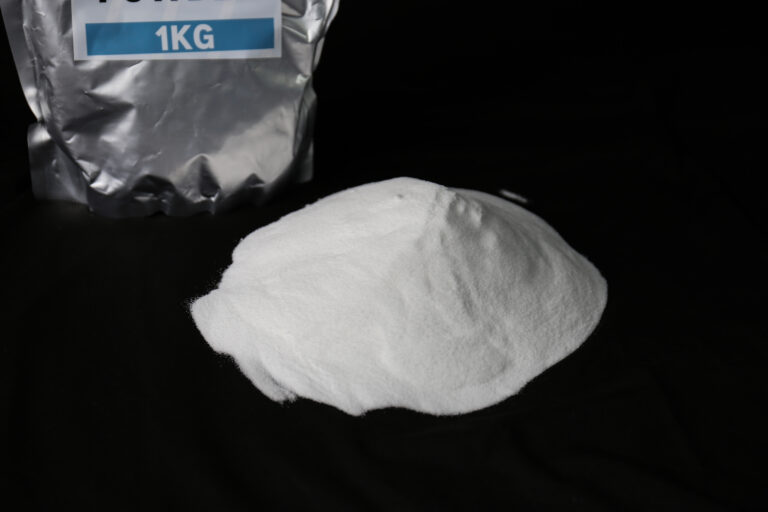

●Powder

The powder is a media that can make the images stick to the substrates. You can regard it as powdered glue. The powder will fully cover the image which is printed right now. Then the covered film can be sent to the oven to heat. After heating, the powder will melt as a layer. This layer will help the images stick to the substrates during the process of heat transferring.

●DTF Ink

DTF ink is thicker than normal ink. Only this kind of ink can provide the image with a higher definition and vivid color. DTF ink’s biggest difference from the other kinds of ink is its white ink. Special white ink is used as the base color of the pattern. This can make the images have no chromatic aberration. The ink will hardly sublimate and is not sensitive to solvents. This means the DTF ink has high color fastness.

●DTF Film Printer

Unlike the piezo inkjet printer, the foam-type printer will change the ink during the process of printing. As a result, we usually use Epson and Sawgrass printers instead of HP and Canon printers. Before we use the printer to print, we must modify the nozzle of the printer. Normally, the nozzle of the printer will be very precise. And the DTF ink is thicker than the normal ink. Only the modified nozzle will be suitable for the DTF ink and provide more output of the ink.

●Oven

The oven used to heat the film must preheat to 140℃-150℃. Or the film will be underheated. The film will be heated for 3 to 5 minutes. The layer of powder will melt as a different and smooth layer which is used to stick the images to the substrates.

●Heat Press

The heat press should preheat to 160℃-170℃. Then we can tile the substrates with the film and heat them for 10~20 seconds. The DTF film can be peeled whether it is cold or not.

How to Operate the DTF?

Firstly, we should modify the nozzle of the printer before printing. After printing, we need to fully spray the powder on average right now after printing and shake the over-sprayed powder down.

Secondly, put the film into the oven to heat the powder on it at 140℃-150℃ for 3-5 minutes. Remember to preheat the oven before you heat it.

Finally, use the heat press to heat transfer the image for 10-20 seconds. Preheating the heat press at 160℃-170℃ helps the image be transferred to the substrates better. By the way, the DTF film can be peeled both at high and low temperatures.

Performance of Desktop DTF

If you don’t know the performance of the DTF solution, let’s dive in to learn more detailed information.

●Vivid Color & Clear Pattern

As we can see in the picture above, the pattern is very vivid and clear. The white ink is used to ensure the brightness of color when the pattern is transferred to the substrates. As a result, the original color of the substrates will have no influence on the color of the patterns. The patterns are clear because of the modified nozzle of the printer. Only the modified nozzle of the printer allows the large output of the DTF ink to make the patterns clear.

●No Cutting Machine

The area which is printed has a stickiness to stick the powder. But, only the film printed just now has stickiness. We must fully stray the powder on average just after the film is printed. Also, only the area printed can be heat transferred to the substrates. As a result, we don’t need to use cutting machines at all.

●No Limitations in Fabrics & Colors

Any fabric and color will have no influence on the effect of transferring. The pattern is stuck to the substrates through the powder. As a result, the kind of fabric has no influence on the transfer. The fabrics like cotton also can be transferred with patterns. As I referred above, white ink is the key to the no limitation of colors. The white ink provides the pattern with a brand-new background and separates the colors of the pattern and the color. So, you don’t have to worry about the limitation of the color of the substrates, too.

●Compact Sizes & Prices

The desktop DTF film is available in A3 and A4 sizes. These compact sizes make desktop operations more convenient and simple. Different from the rolled DTF film, desktop DTF film is also very comfortable for you to test samples in the beginning. It prevents you from wasting the films. What’s more, according to our calculations, the cost of each A4 size pattern is less than 0.225 dollars. This price is much lower than other transfer methods.

Conclusion

Desktop DTF provides manufacturers with the easiest method to try DTF solutions. This operation also can help the manufacturers to experience the excellent effect of DTF solution. The vibrant color and fine pattern will surprise you a lot. All of the materials can be found on our official website. If you have interested in the DTF solution, welcome to email and contact us. We will provide you with the best service.