During this time, DTF Heat transfer film is a hot word in the transfer industry. Many people, including dealers, expressed interest in DTF Heat transfer film. So how much do you know about DTF Heat transfer film? Is DTF heat transfer film better than sublimation paper?

DTF Heat transfer film and sublimation paper have their own characteristics. DTF is superior to sublimation paper in terms of scope of application, pattern clarity and cost.

Let’s take a closer look at the difference between DTF Heat transfer film and sublimation paper.

Differences Between DTF Heat Transfer Film and Sublimation Paper

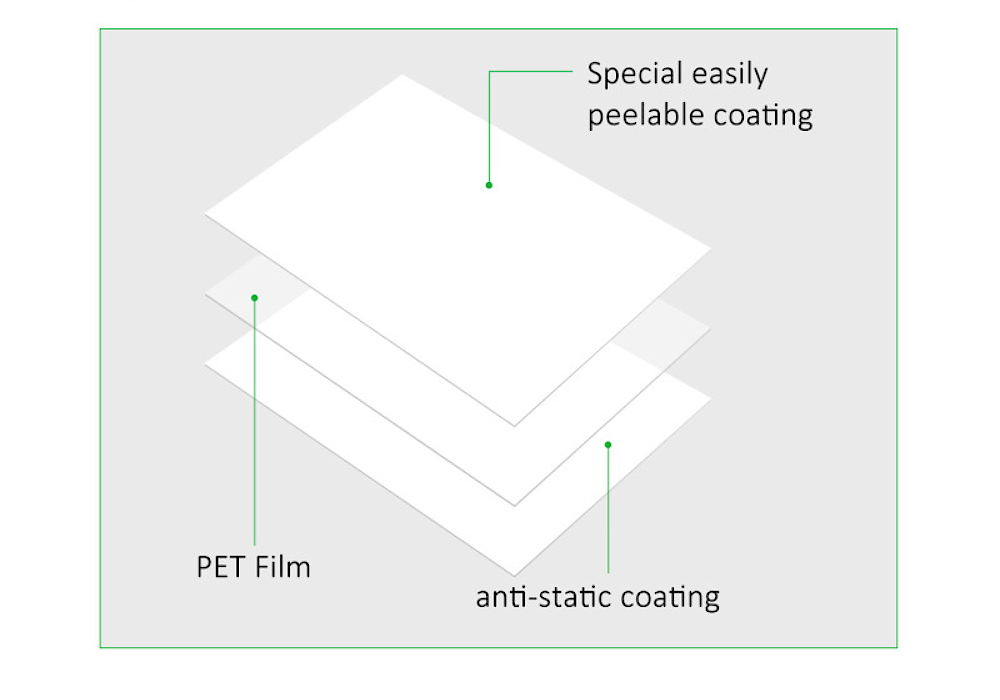

Consumables Structure

DTF Heat transfer film is a medium material for heat transfer process. The pattern printed on PET heat transfer film is transferred on the clothes through the ink sticky hot melt powder that on the surface of the pattern as the transfer medium.

The structure of DTF Heat sublimation film and Sublimation paper is different, only a layer of transfer film consist of anti-static coating, PET film and peelable coating. The sublimation paper is composed of base paper and films.

Inks

Similar to sublimation paper, DTF Heat transfer films require a specific ink – DTF Pigment Ink. DTF Pigment ink is a special water-based pigment ink. It is mainly used for direct jet printing on cotton, line, and cotton blended fabrics, such as glue screen printing,digital printing. The pattern transfer with DTF Pigment ink has bright color and good color fastness. At the same time,the pattern is no fade.

It must be mentioned that DTF Pigment Ink has strong ink absorption and clear layer.

DTF ink is pigment ink with large molecular structure. It has more vivid colors and high pattern clarity. The sublimation ink is a disperse dye ink with a small molecular structure and is easy to sublime. However, the pattern clarity may be lower than that of the DTF pigment ink.

DTF ink has white ink as the base color and can be attached to any color of fabric. This is one of the major advantages of DTF over sublimation transfer.

Equipment requirements

It is precisely because the ink required for DTF Heat transfer film and the ink required for sublimation paper are different in composition and molecular size. So sublimation printers are not suitable for heat transfer films.

However, the modding process is also not very complicated. If you need to use a sublimation printer to print a pattern on the DTF heat transfer film, then you need to replace the printer’s nozzle in advance.

At present, for the convenience of customers, our company also provides an integrated DTF Printer, which integrates from printing to heating.

Operation steps

The operating steps of DTF are somewhat different from those of sublimation transfer. The first step is to spread hot melt powder. It should also be noted that the water-based ink needs to be cold-teared. Specific steps are as follows.

1. Digital Printing(Color Ink first, White Ink second)

Use professional software to draw the picture, then use the printer to print the pattern on the PET transfer film.

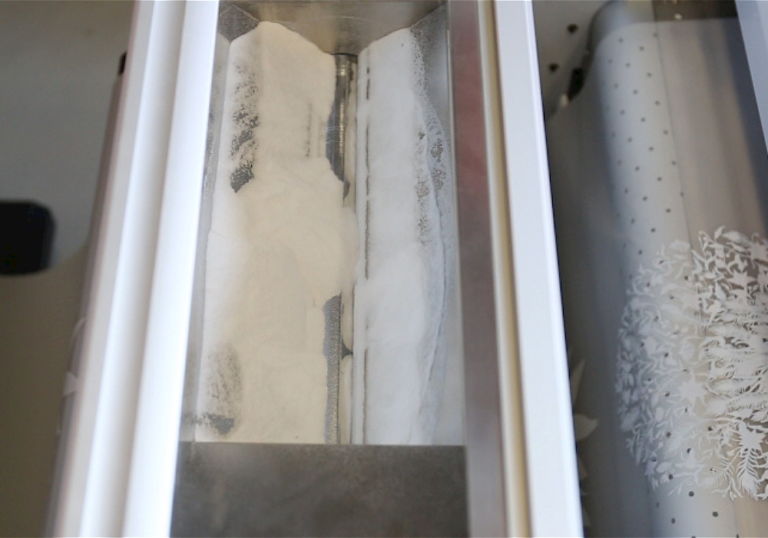

2. spreading the melt powder and shake power

Sprinkle an appropriate amount of hot-melt powder on the printed PET film, and shake off the excess hot-melt powder.

3.Drying( Temperature: 130 ℃, 5-8mins)

Put the PET film on the oven/microwave oven for 5-7 minutes, until the hot melt adhesive powder melts, and take out the PET film.

4. Heating transfer( 150℃ to 160℃, 10s)

Lay the T-shirt flat on the heat transfer machine, paste the side with hot melt glue on the T-shirt for pattern hot stamping, the heat transfer temperature is 150-160 ℃, and press for 10 seconds.

5.Tear

Finally, you can tear the film.

If you want to understand the steps more clearly, you can watch the video below.

Application range

I believe everyone has a question. We are using sublimation paper well now. Why do you recommend this DTF Heat transfer film to me?

Although sublimation paper is easy to use, it has requirements for blanks. Blanks of light-colored polyester fiber material are required. DTF transfer film is suitable for fabrics of various colors because it has white ink as base. And because it is transferred to the fabric by hot melt adhesive, the DTF Heat transfer film can be used for different kinds of fabrics.

Transfer results

The colorant of DTF Heat transfer film is different from that of sublimation paper, their transfer results are also different.

Compared with the pattern transferred by sublimation paper, the color performance of DTF heat transfer film is better.

Dye sublimation Ink cannot express white and cannot transfer dark fabrics, but DTF transfer Ink can do it. The DTF transfer film has white ink as base, it do not pick the color of the fabric.

Moreover, the DTF transfer film uses water-based pigment ink, and the transferred image has high definition.

Compared with sublimation paper, the pattern transferred by DTF has high light fastness and is not easy to fade.

Touch Feeling

The texture of the pattern transferred from DTF heat transfer film and sublimation paper is different. Since the pattern is transferred on the fabric by hot melt adhesive, it is tactile. This is also different from sublimation paper.

Advantages

DTF Heat transfer film has many advantages over sublimation paper, which are listed below.

Inexpensive

As a wholesaler, everyone must pay more attention to the price. Using DTF heat transfer film is more affordable than sublimation transfer.

It can easily convert traditional inkjet printers to DTF printers, so you can enjoy the convenience and efficiency of DTF printing technology without spending a lot of money.

It is suitable for customized industries that need to make a small amount of variety, and it is also very suitable for small businesses.

Easy operation

DTF Heat transfer film has fewer steps in operation than sublimation transfer. It is more convenient to operate.

DTF has the advantage of free version and no pick characters. It does not need to cut the graphics through the word cutter.

DTF uses the principle of hot melt adhesive powder adhering to ink, any complex graphics can be easily transferred and in place at one time. This overcomes the problem that the word cutter cannot cut too small and broken graphics.

DTF can be easily transferred through a thermal transfer machine, giving the cultural and creative industry more design space, making the printing of fabrics more flexible and more convenient.

More details in the transferred pattern

It can printing of very small patterns and texts, as well as multi-color printing. The article mentioned above that the pattern transferred by DTF thermal transfer film is clearer due to the use of water-based pigment ink. This is why DTF transfer film can better display pattern details.

Wide applicability

DTF can be applied to a wide range of materials, including various shades of canvas, cotton T, sweatshirts, denim, nylon and other textile materials. It provides more possibilities for customized product printing. Therefore, it offers more possibilities for customizing the printing of goods, but also more diverse products that can be printed.

Not easy to fall off under the sun

The pattern transferred from DTF heat transfer film has strong light fastness and is not easy to fade.

Washable

DTF Heat transfer film not only has strong sun fastness, but also has strong washing fastness. It is not easy to fall off with normal washing and cleaning.

Tips

However, the following two points need to be paid attention to when using DTF Heattransfer film.

Time consuming

DTF printing is not that fast. However, multiple pictures can be printed together, so the time-consuming is not too long. It’s just that it’s slower than sublimation transfer.

poor air permeability

Because the DTF Heat transfer film transfers the pattern to the fabric through hot melt adhesive, the pattern it transfers has a soft texture. This also leads to its air permeability is not as good as sublimation paper.

What changes are needed to switch from sublimation transfer to DTF heat transfer?

The transition from sublimation transfer to thermal transfer film is actually not difficult, all you need to do is change the head of the printer.

At the same time, our company provides you with a one-stop machine that integrates DTF printer and powder shaker.

It has Smart PLC Touch screen.Equipped with an easy-to-use touch screen. Navigate the menu by simply touching the desired option.

The paper feed and take-up with tension system allows you to complete production unattended for a simple and precise workflow from printing to loading and feeding through the roll-to-roll securely wound.

It has infrared drying function. Adjustable temperature infrared and heating drying improves and protects color reproduction.

Vacuum adsorption conveying platform, absorbing the print material to ensure that the material does not bulge or run off.

Integrated purifier for the option to replace of exhaust pipe make the use of the machine more convenient.

Conclusion

DTF Heat transfer film is a very distinctive transfer consumable.

Unlike sublimation paper, the pattern transferred by DTF heat transfer film can be comparable to the pattern transferred by DTG.

At the same time, DTF is affordable and suitable for high-volume transfer. The pattern transferred from the DTF heat transfer film is not easy to fall off and fade.

In general, if you are interested in DTF thermal transfer film, you can still try it.