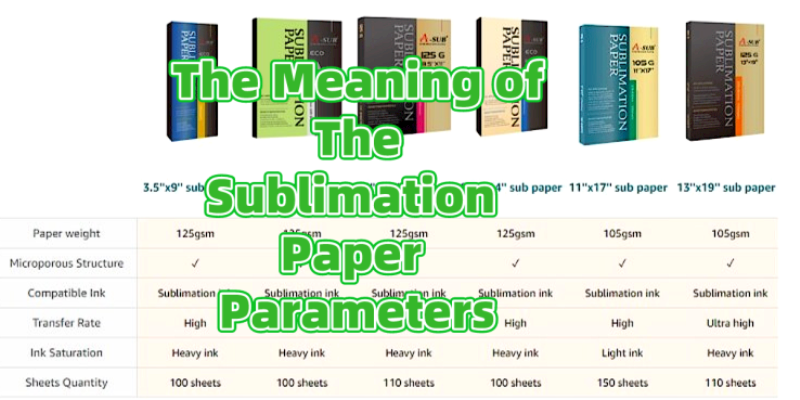

When you import sublimation paper, you should often see various parameters on the product packaging. The parameters of sublimation paper are also listed in detailed map on line. What do these parameters mean? Do you really understand these parameters?

In fact, when we buy sublimation paper, we mainly consider the following four parameters, including weight, size, number of sheets, and coating.

Now allow me to introduce these four parameters and how to choose sublimation paper with different parameters in detail.

Item weight

The meaning of item weight

The grammage refers to the weight of the paper per square meter before cutting. When cut to a size suitable for retail packaging, there are three options: 105g, 120g, and 125g.If the dimensions are exactly the same, the difference between different weights of sublimation paper is the thickness of the paper.

The variation in thickness is related to the paper itself and the amount of sublimation coating. Thicker coating, more saturated sublimation paper can handle saturation of thick ink more effectively. Thinner sublimation paper is ideal for your light ink saturation needs.

The difference between sublimation paper with various weight

Take A-sub sublimation paper as an example.

A-sub 105g sublimation paper is best for designs with light to medium ink saturation.

A-sub 120g sublimation paper is best for medium to light saturation ink designs.

A-sub 125g sublimation paper is best for printing designs with very high ink saturation.

If your work is going well and your design is clear, then you must have the right paper. However, if any of the following problems occur, try to replace the paper.

If your paper is often curl, choose a sublimation paper that is heavy in grams. My paper always have wheel marks-go in the opposite direction. If the problem persists, clean your printer thoroughly.

If you often print a design that includes both light ink saturation and heavy ink saturation, please keep in the middle of 120 grams. If you use 105g, the heavy part of the design may move, bleed or double-image.

If your hard blank is ghosting-the ink has nowhere to go, and there may be too much to deal with. Go to the lowest grammage.

If your T-shirt looks faded, but all the ink is transferred

The grammage needs to be increased because it accepts more ink.

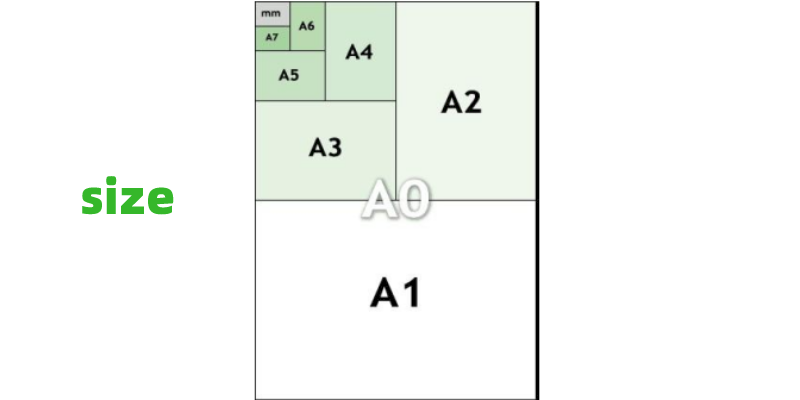

Sheet size

The meaning of sheet size

As the name implies, the size of the sublimation paper refers to the length and width of the sublimation paper after cut.

When we consider the size of the sublimation paper, we should pay attention to the size of the blanks, the size of the pattern, the position of the pattern and so on.

The different application of sublimation paper with different sheet size

Now let me give some examples. When the transfer pattern on the mug, we usually choose the sublimation paper with small size. When we want to transfer a pattern on a T-shirt, we usually choose a slightly larger size, which of course also depends on the size of the pattern.

Furthermore, the size of the sublimation paper used for the transfer pattern on the clothes of adults and children is different.

Number of items

The amount of sublimation paper is easy to understand. When we import sublimation paper, we need to consider our specific use. For retail, you can choose sublimation paper with smaller packaging. This way, the number of paper is smaller and easier to sell. If it is for factory work, then we can choose sublimation paper in large package.

Coated

The meaning of coated

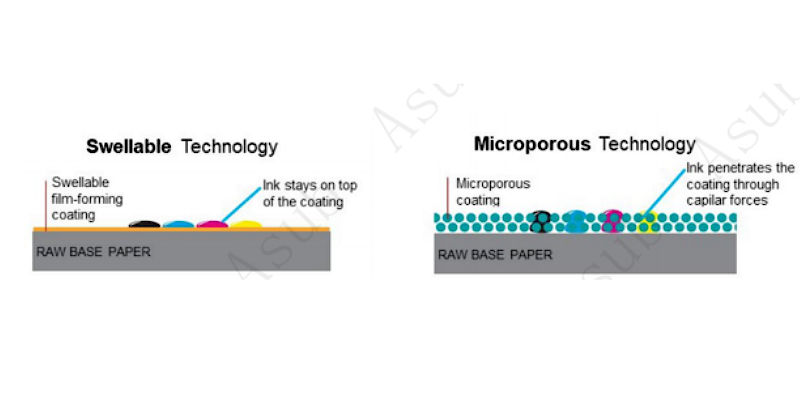

Sublimation paper consists of base paper and coating. Currently, there are three sublimation papers with different coatings on the market, including swelling sublimation paper, microporous sublimation paper and multi-layer microporous sublimation paper.

Different effects of coatings

Swellable Sublimation Paper is the First Generation. This sublimation paper is made by coating it with organic polymers, like gelatin. This coating swells up to surround the sublimation ink once the ink strikes the paper.

In layman’s terms, when the swellable sublimation paper is working, the ink is attached to its surface. So it’s not hard to figure out that it has excellent image finish and print durability.

However, swellable paper is more sensitive to contact with water and highly humid environments. As a result, the produced prints also require longer drying times.

This posed a problem as ink jet printers tended to print faster than the sublimation ink could dry. Consequently, another form of paper has gained prominence.

The Performance of Microporous Sublimation Paper is Better. Microporous coatings are alumina or silica in tiny, inorganic particles that create voids or cavities in the coating. The sublimation ink is then absorbed into these cavities by capillary action.

As a result, microporous papers have high resistance to moisture and humid conditions. That is to say, microporous papers help produce rapidly drying prints. It solves the problem of swellable papers.

Of course, in terms of transfer rate, warpage and other properties, microporous paper is also better.

It is worth mentioned that our company has developed multi-layer microporous sublimation paper. It is better than microporous sublimation paper in various performances.

If you have a large production volume and sufficient funds, it is recommended that you choose microporous paper. However, the choice should also be based on reality and choose the most suitable one.

Conclusion

As practitioners, we need to fully understand the parameters of the sublimation paper. Only by knowing enough, we will know how to purchase sublimation paper in bulk.

The properties of different coated sublimation papers are different. It directly affects the ink compatibility of the sublimation paper and even the final transfer effect.

The grammage of the sublimation paper is also affected by the coating. At present, the difference between sublimation papers with the same size and different weights is that the thickness is inconsistent. The transfer objects of sublimation paper of different thickness are also different.

Finally, we also need to import sublimation paper of different sizes and quantities according to our actual needs.