Intro

With businesses increasingly relying on stickers for branding, marketing, and product labeling, inkjet sticker paper becomes imperative to grasp the correlation between gram weight and inkjet sticker paper quality. How gram weight affects inkjet sticker paper quality?

Stick paper gram weight refers to the weight of a one-square-meter sheet of inkjet sticker paper, measured in grams per square meter. It serves as a crucial indicator of the paper's thickness, stiffness, ink absorption capacity, and overall print quality.

However, understanding the basics of gram weight is just the beginning. In the sections that follow, we'll dive deeper into how factories ensure the accuracy of gram weight measurements for inkjet sticker paper and unveil the extensive impact it has on various aspects of paper quality. By gaining a comprehensive understanding, you'll be equipped with the knowledge necessary to make informed decisions when selecting inkjet sticker paper for your business needs.

What is Gram Weight in Inkjet Sticker Paper?

Gram weight of sticker paper is the weight of the paper used for printing stickers using an inkjet printer, determining the quality and characteristics of sticker paper. It is an important factor to consider when selecting inkjet sticker paper as it affects the overall durability, appearance, and performance of the printed stickers.

Higher gram weights indicate thicker and sturdier paper, which results in more durable stickers. Sticker papers with lower gram weights may be more lightweight and can be prone to tearing or curling. When using an inkjet printer, the gram weight of the paper is particularly important because it determines how well the paper can absorb and hold ink. Papers with higher gram weights have a higher ink absorption capacity and produce better color saturation, sharper images, and more vibrant prints. They also minimize ink bleed or smudging, resulting in crisper and more professional-looking stickers.

How do factories ensure that the gram weight of the inkjet sticker paper is accurate?

Factories that produce inkjet sticker paper employ several measures to ensure the accuracy of the gram weight.

●Quality Control Testing

Factories conduct regular quality control testing to verify the gram weight of the inkjet sticker paper. This involves randomly selecting samples from the production line and measuring their weight using precise scales. These measurements are compared against the targeted gram weight specifications to ensure compliance.

●Standard Operating Procedures

Factories establish standard operating procedures (SOPs) for the production of inkjet sticker paper. These SOPs outline the specific requirements and guidelines for achieving the desired gram weight. They include detailed instructions on raw material selection, paper manufacturing processes, and quality control checks at various stages of production.

●Raw Material Control

The factories carefully control the selection and storage of raw materials used in the production of inkjet sticker paper. The paper pulp or base material chosen should have a consistent and known gram weight. By ensuring that the raw materials meet the desired specifications, factories can maintain consistency in the gram weight of the final product.

●Statistical Process Control

Factories employ statistical process control techniques to monitor and control the gram weight of the inkjet sticker paper during production. This involves collecting and analyzing data at regular intervals to identify any variations or trends that may affect the gram weight. By closely monitoring the manufacturing process, factories can take corrective actions promptly to maintain the desired gram weight within acceptable limits.

By implementing these measures, factories can ensure that the gram weight of the inkjet sticker paper remains accurate and consistent throughout the production process. These quality control practices help maintain the desired specifications, providing customers with reliable and predictable results when using the sticker paper.

How gram weight affects inkjet sticker paper quality?

Gram weight, also known as grammage or paper weight, plays a significant role in determining the quality and characteristics of inkjet sticker paper. It affects various aspects of the paper, including its thickness, stiffness, ink absorption, printer feedability, surface quality, drying time, compatibility with different inks, suitability for transfer print technology, and ability to accommodate different resolutions. Let's delve into each aspect in detail:

●Thickness and Stiffness

Gram weight directly influences the thickness and stiffness of inkjet sticker paper. Higher gram weights result in thicker and sturdier paper, while lower gram weights indicate thinner and more flexible paper. Thicker paper provides better durability, preventing tears or curling, and offering a more substantial feel to the stickers. Stiffer paper is easier to handle and facilitates smooth application onto various surfaces.

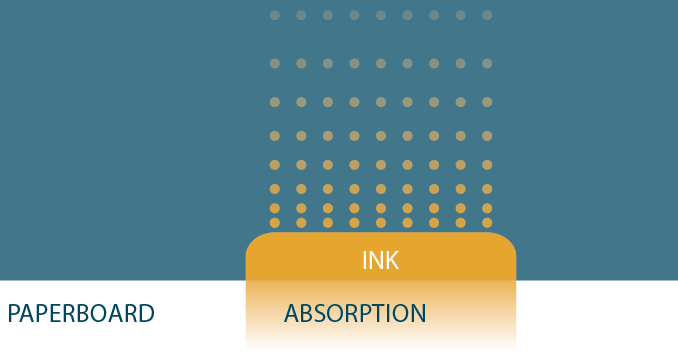

●Ink Absorption

Gram weight affects the ability of inkjet sticker paper to absorb ink. Higher gram weights generally have higher ink absorption capacity, allowing for better color saturation, vibrant prints, and sharper images. The increased ink absorption minimizes ink bleeding or smudging, resulting in crisper and more professional-looking stickers.

●Printer Feedability

The gram weight of the paper influences its ability to feed through an inkjet printer. Lighter-weight papers tend to be more prone to jams or misfeeds, especially if the printer's feeding mechanism is not adjusted accordingly. Heavier gram weights provide better stability and feeding reliability, ensuring smooth printing without disruptions.

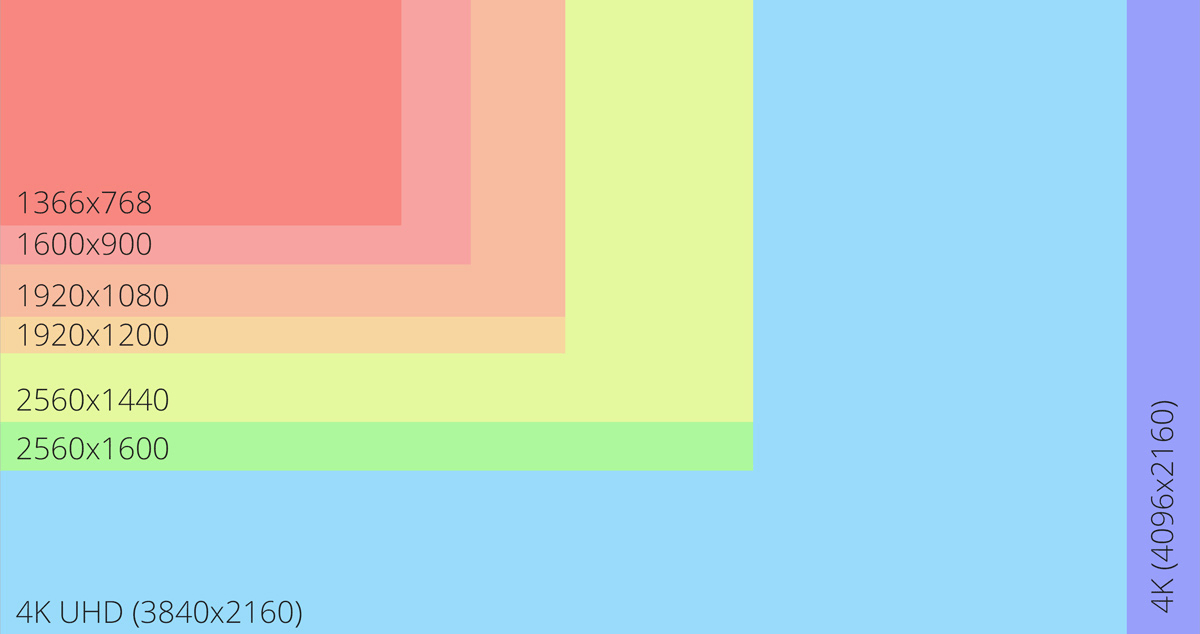

●Surface Quality

Gram weight affects the surface quality of inkjet sticker paper. Higher gram weights generally result in smoother surfaces, which contribute to better print resolution, fine detail reproduction, and overall print quality. Smoother surfaces also enhance the adherence of the ink to the paper, minimizing issues like feathering or ink pooling.

●Drying Time

The gram weight of the paper can influence the drying time of the ink. Heavier paper tends to absorb ink at a slower rate, which can extend the drying time. Conversely, lighter-weight papers may have faster drying times due to their lower ink absorption capacity. Proper drying time is crucial to prevent smudging or smearing of the printed stickers.

●Compatibility with Different Inks

Gram weight can impact the compatibility of inkjet sticker paper with different types of inks. Some inks may require specific paper weights to achieve optimal results. For example, pigment-based inks often perform better on higher gram weight papers, while dye-based inks may work well on a wider range of paper weights. Manufacturers usually provide recommendations regarding the suitability of their inks for specific gram weights.

●Resolution Suitability

Gram weight can influence the suitability of inkjet sticker paper for different resolutions. Higher gram weights are generally better suited for high-resolution printing, as they offer better ink control, finer detail reproduction, and crisper lines. However, it's important to note that advancements in printer technology and paper coatings have made it possible to achieve good results with lower gram weights as well, depending on the specific printer and ink combination. In summary, gram weight has a significant impact on the quality and performance of inkjet sticker paper. It determines the thickness, stiffness, ink absorption, printer feedability, surface quality, drying time, ink compatibility, and resolution capabilities. Choosing the appropriate gram weight is crucial to achieve the desired results in terms of print quality. If you have more questions about sticker paper, you can click the link below to learn more. A-SUB Sticker Blog

Conclusion

In conclusion, the gram weight of inkjet sticker paper plays a crucial role in determining its quality and performance. It directly impacts the thickness and stiffness of the paper, ensuring durability and ease of handling. The gram weight also affects the paper's ability to absorb ink, resulting in vibrant and smudge-free prints. Furthermore, it determines how smoothly the paper feeds through printers, preventing jams and ensuring consistent printing results. Different gram weights offer a range of surfaces, influencing drying time and making the paper compatible with various inks and printing technologies. Additionally, gram weight considerations are essential for achieving optimal resolution and image quality. By understanding and selecting the appropriate gram weight, businesses can elevate their printing capabilities and deliver exceptional results to clients and customers alike.