Intro

There are several factors to consider when selecting transfer paper for fabrics of different materials. The type of fabric, the color of the fabric, the transfer method, etc. Then, how do we choose the right transfer paper for the different type of fabric?

First of all, we need to classify the materials of fabrics in the market into cotton, polyester and mixed fabrics. Then, according to the characteristics of these fabrics to select the appropriate transfer paper.

This article focuses on several types of transfer paper and explains which materials they are suitable for.

T-shirt transfer paper

When it comes to T-shirt transfer paper, there are a variety of fabrics you can use, but the most commonly recommended fabrics are 100% cotton, 50/50 cotton/polyester blends, and polyester. There are about three types of T-shirt transfer paper on the market.

Inkjet transfer paper for light cotton fabrics. This type of transfer paper is used to transfer designs onto white or light cotton fabrics. This paper has a thin, transparent film that allows the design to transfer smoothly onto the fabric.

Dark cotton inkjet transfer paper. This type of transfer paper is used to transfer designs onto dark cotton fabrics. This paper has a white background that helps the design stand out on the fabric.

Laser Transfer Paper. This type of transfer paper is used to transfer designs to a variety of fabrics, including cotton, polyester, and blends. This paper uses toner that is transferred to the fabric using heat and pressure.

It’s important to note that not all transfer papers will work with all fabrics, so be sure to read the instructions carefully and test your transfer paper on a small area of fabric before starting your project. Also, always follow the washing instructions for the transfer paper and fabric to ensure that your design lasts as long as possible.

DTF Film

Direct to film transfer is a process where designs or graphics are printed directly onto a clear film, and then transferred onto fabric using heat and pressure. The choice of fabric for direct to film transfer can affect the quality and durability of the transfer, so it’s important to choose fabrics that are suitable for this process.

The most suitable fabrics for direct to film transfer are those that have a smooth and flat surface, and are able to withstand high temperatures without melting, scorching, or shrinking. Some examples of fabrics that are commonly used for direct to film transfer include:

Polyester: This is a synthetic fabric that is commonly used for direct to film transfer because it has a smooth surface and is able to withstand high temperatures. It is also known for its durability and resistance to shrinking and fading.

Nylon: This is another synthetic fabric that is suitable for direct to film transfer because it has a smooth surface and can withstand high temperatures. It is also known for its strength and durability.

Cotton: While cotton is not the ideal fabric for direct to film transfer, it can be used if it has been treated with a coating that allows the transfer to adhere properly. However, cotton is more prone to shrinking and wrinkling, so it may not be as durable as synthetic fabrics.

Blends: Fabric blends that include polyester or nylon are also suitable for direct to film transfer, as they combine the durability and strength of synthetic fabrics with the natural look and feel of cotton.

In addition, DTF is best to consult with a professional or do a test run before attempting to transfer a design onto fabric.

Sublimation Paper

Sublimation paper is primarily used to transfer designs to polyester fabrics, which can produce vibrant and durable results. However, not all polyester fabrics are created equal, and some work better with dye sublimation than others. Here are some of the most common types of polyester fabrics that are suitable for dye sublimation printing:

Polyester blends: These fabrics are made from a combination of polyester and other fibers, such as cotton or rayon. While not as vibrant as 100% polyester fabrics, they can still produce good results with dye sublimation printing.

Polyester mesh: This type of fabric is often used for sports jerseys and other athletic apparel. Its breathable mesh construction makes it ideal for dye sublimation printing because the ink can penetrate the fabric more easily.

Polyester Fleece: Fleece is a popular fabric for jackets, blankets, and other cold-weather gear. It is also suitable for dye sublimation printing, although the results may be less vibrant than other polyester fabrics.

Polyester Spandex: This fabric is often used for sportswear and other form-fitting garments. Its stretchy, moisture-wicking properties make it ideal for dye sublimation printing, although it can be more difficult to work with than other polyester fabrics.

In addition to these polyester fabrics, other materials that can be sublimated include ceramics, metals, and certain types of plastics that have a polymer coating.However, it’s important to note that dye-sublimation paper is not suitable for use with natural fibers such as cotton, wool, or silk because they do not have a polymer coating and do not bond with the dye in the same way that polyester does.

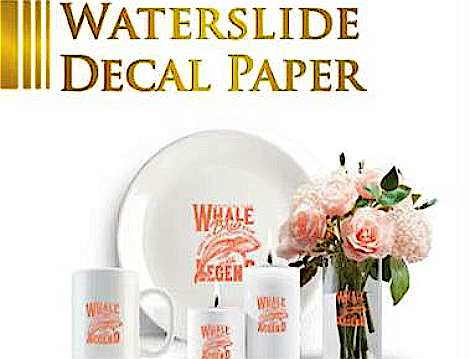

Water Slide Decal Paper

Waterslide decal papers can be used to transfer printed designs to a variety of surfaces, including fabrics. However, not all fabrics are suitable for use with waterslide decals.

The most suitable fabrics for waterslide decals are those that are tightly woven and have a smooth surface. This allows the decal to adhere properly and smoothly to the fabric. Some of the fabrics commonly used for waterslide decals include: cotton, silk, polyester and nylon.

HTV

For heat transfer vinyl , the type of fabric you use can have a big impact on the adhesion and duration of the transfer. So in addition to cotton and polyester, which are two types of fabrics, HTV can also be used for blends, canvas, and leather transfers.

Blends: Many fabrics are blends of cotton and polyester or other materials. In general, blends with at least 50% cotton content work well with HTV transfer paper.

Canvas: Canvas is a strong and durable fabric typically used for bags, backpacks and other items that require durability. It is suitable for HTV transfer paper because it can handle the high temperatures required for heat transfer printing.

Leather: While it may be more difficult to handle, leather is another fabric that can be used with HTV transfer paper. Just be sure to test a small area first to make sure it can handle the high temperatures.

In general, it is best to test a small area of the fabric to be used with HTV transfer paper before proceeding with a large project. This will help you determine if the fabric can withstand the heat and pressure required for heat transfer and if the transfer will adhere properly.

Conclusion

In General, after analyzing the four kinds of transfer papers – inkjet, laser, sublimation, and vinyl – it is evident that each type is suitable for specific fabrics based on their unique features.

Inkjet transfer paper is best suited for fabrics that are light-colored and made of natural materials, such as cotton and silk. The transfer paper’s water-based ink is designed to bond with the fabric fibers, creating a soft and vibrant design.

Laser transfer paper, on the other hand, is best suited for fabrics that are darker in color and made of synthetic materials, such as polyester and nylon. The transfer paper’s heat-activated toner is ideal for bonding with the synthetic fibers, creating a durable and long-lasting design.

Sublimation transfer paper is designed for fabrics made of polyester or polyester blends. When heat is applied to the paper, the ink turns into a gas, which then penetrates the fabric’s fibers, resulting in a long-lasting, vibrant, and durable design.

It is essential to note that the suitability of transfer papers for specific fabrics is not limited to the factors mentioned above. Other variables, such as the type of printer used, the fabric’s texture, and the transfer paper’s quality, can also affect the transfer’s final result.

Differently, Waterslide decal papers can be used to transfer printed designs to a variety of surfaces, including fabrics.

In addition to cotton and polyester, which are two types of fabrics, HTV can also be used for blends, canvas, and leather transfers.

In conclusion, choosing the right transfer paper for your fabric is crucial in achieving a long-lasting, vibrant, and personalized design. Consider the fabric’s color, texture, and composition, as well as the transfer paper’s features, before making your decision. With the right combination of fabric and transfer paper, you can create stunning designs that will last for years to come.