There are already many brands on the market that are producing and selling DTF transfer film. We should have a ruler in mind to measure the quality of DTF transfer film. So how to test DTF transfer film?

DTF is different from other heat transfer papers. It is special and consists of only one layer of film.

When we test, we need to combine its working principle, and test it from various aspects such as the condition of white ink printing, the quality and texture of the transfer pattern and so on.

Next, let’s take a look at how to test the DTF transfer film in detail.

Brief Introduction of DTF Transfer Film

DTF Heat transfer film is a medium material for heat transfer process. The pattern printed on PET heat transfer film is transferred on the clothes through the hot melt powder that on the surface of the pattern as the transfer medium.

The structure of DTF Heat sublimation film and Sublimation paper is different, only a layer of transfer film consist of anti-static coating, PET film and peelable coating.

How To Test DTF Transfer Film?

Now, I will introduce several aspects of testing DTF transfer film from a professional point of view.

White ink printing

Everyone should know that the great advantage of DTF is that you don’t need to choose the color of the fabric. In fact, this is because the DTF transfer film has white ink as the base when printing the pattern, the transferred pattern will not be affected by the color of the fabric.

It can be seen that when printing patterns on DTF transfer film, the quality of the white color is very important.

In general, 80%, 100% white ink printing on DTF transfer film is normal.

Waterside

Some DTF transfer films on the market have printed patterns with water edges. The edge with water will cause the edges of the printed pattern to be powdered, which will eventually make the transfer effect unsatisfactory.

So when printing the pattern on the DTF transfer film, we should also pay attention to the edge of the pattern.

Whether to support hot and cold tearing

Regarding the issue of cold tearing or hot tearing, most manufacturers still recommend cold tearing, because most DTF inks on the market are water-based inks. However, after continuous research and development, some DTF transfer films support both cold tearing and hot tearing.

The saturation of Pattern

The saturation of the pattern is also a very important indicator for testing the DTF transfer film.

The pattern transferred by DTF is comparable to that of DTG. The saturation and clarity of the pattern transferred by good DTF transfer paper are very high.

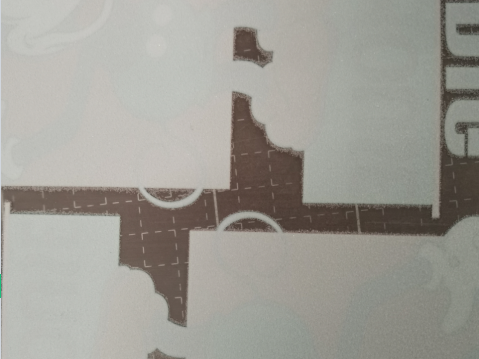

Whether the pattern is mottled

When we print the pattern on the DTF transfer film, we can see if the pattern has pinhole-sized white spots through the light.

When we tested the DTF transfer film on the market, we found that the pattern printed on some inferior DTF transfer film can see white spots like pinholes through light. This is actually a very serious problem, which will directly affect the final transfer result.

Appearance of coating

A great DTF transfer film prints out a pattern coating that is evenly distributed without graininess.

However, even if the surface of the coating is grainy, the pattern is not greatly affected after the transfer. If you are more concerned about graininess, you need to pay attention to this point.

Oil return

When we test the DTF transfer film, we should pay special attention to the problem of oil return. From the sensory point of view, the oil will have a relatively large impact on the look and feel, and in some ways it may also slightly affect the saturation of the color.

Good DTF transfer film rarely has this problem.

some brands of DTF transfer film anti-oil is because the chemical substance of the ink has not completely evaporated during the transfer process. After a period of time, it can generally recover freely. Alternatively, increasing the temperature during transfer can avoid this problem.

About A-sub

A-sub R&D department has conducted a lot of professional tests on the various properties of DTF, including the saturation of the transfer pattern, whether there is anti-oil and so on. After testing, it is not difficult to find that when the A-sub DTF transfer film and ink are used together, the saturation of the transferred pattern is higher than that of other DTF transfer films on the market.

A-sub also tries to avoid the problem of anti-oil in the pattern transferred by DTF on the market. At the same time, The pattern transferred from the A-sub DTF transfer film is bright in color and has almost no oil reflection. It absorbs ink well, resists rubbing, and the surface feels smooth, non-sticking, and scratch-free. At present, the A-sub DTF transfer film supports hot and cold tearing and is resistant to stretching.

In addition to the above advantages, the pattern transferred with A-sub DTF consumables has no irritating odor and is not easy to fall off. Suffice it to say, you can fully trust A-sub when it comes to quality.

Conclusion

Because DTF transfer printing is different from other Heat transfer printing. Therefore, the test of DTF transfer film cannot follow the method of sublimation paper or even T-shirt transfer paper. We need to test and analyze from multiple dimensions according to the transfer principle of DTF transfer film, and not to miss the small details.

The six aspects in this article are given by professionals, and they are also points that everyone needs to pay more attention to when testing. Of course, if you have other perspectives, you are also welcome to contact us.

I hope this article can be helpful to you.