Sublimation printing is used more and more in our daily life. Various problems will inevitably occur during the transfer process. So what problems will be encountered in sublimation printing?

The process of Sublimation printing may exists various problems such as Banding, Moisture issue, ect. Most of these problems are affected by the quality of the transfer paper, the quality of the printer, and the proficiency of human operation.

Now let’s discuss common problems and solutions in the sublimation printing process.

What Problems Will be Encountered in the Process of Sublimation Printing?

As I mentioned, There are all kinds of problems in sublimation printing. In general, these problems are almost all related to printing equipment, transfer paper and manual operations. Some questions may involve several aspects.

Problems Related to Printing Equipment

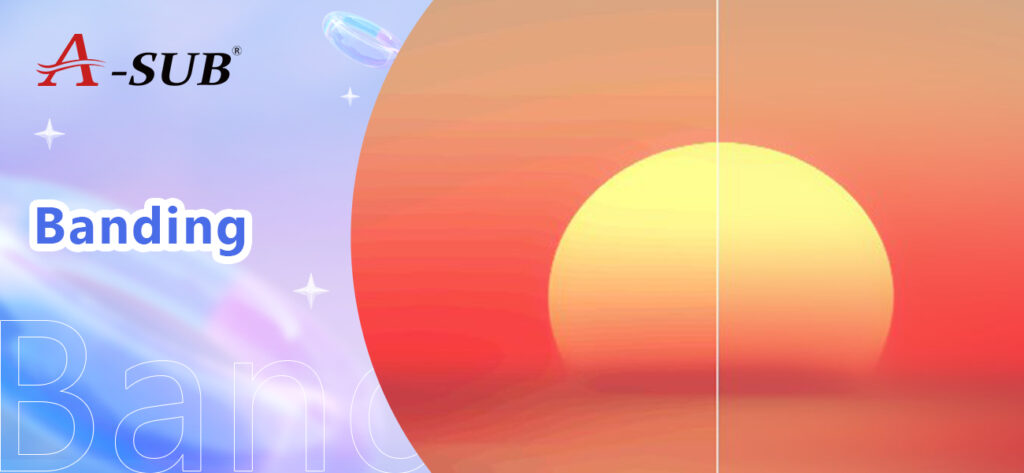

Banding

When you print a sublimation paper, you may notice a visible blank line or area and lack of print, this is called banding.

Banding is the most common problem in all digital inkjet printing systems. This is generally caused by clogged print nozzles. Sometimes it may also be caused by running out of ink and so on.

Extra Ink

Sometimes, you’re pressing a design on a shirt and you have a small blotch off to the side.

Maybe your printer got a little smudge off to the side, and you didn’t even notice it. Then, you get that extra ink on your shirt unfortunately.

If you see extra ink on your print, you can cover it with heat-resistant tape before you press. By this way,the extra bit of ink doesn’t transfer onto your shirt. Remember any ink on that piece of paper is going to transfer to your shirt no matter how small it is.

Output Colors Are Incorrect.

Color mismatch issues are usually not the result of a flawed system, but rather the result of multiple image rendering devices involved in the process. Each image rendering device has a different color management method and range.

Problems Related to Transfer Paper and Blank

Moisture Issues

Moisture Issues can cause unwanted results. If the paper has high moisture content or ink is not dry, ink cannot be able to transfer to its intended target and results in bleeding of image and ghosting problem as well as color shifting.

Under normal conditions, a small amount of moisture accumulates in the transfer paper. It is usually absorbed directly into the substrate during pressing.

However, hard substrates such as metals and ceramics cannot absorb excess moisture. Therefore, you must take steps to minimize the amount of moisture.

Wrong Blank

When you see blanks or lighter areas in the pressed sublimation, it may be due to uneven heat from the heat press or moisture on the sublimation blank.

Sublimation requires high temperatures to come out properly. Moisture prevents heat, so your design doesn’t transfer completely to your blank.

Faded Print

If you choose a blank that polyester fiber content is less than 30%, you will get a faded pattern after transferring. This is because the sublimation ink will only permanently transfer to the polyester portion of the fabric.

Too much time, too much temperature, or even too much pressure can make your print look faded.

Problems Related to Manual Proficiency

Ghosting

Ghosting is when the print ends up with blurry images and shadow-like images. If the paper is displaced or not seated firmly against the heat press or the ink does not dry during pressing, the pattern will be ghosting.

When ghosting occurs, all the printing efforts of the manufacturer are in vain, obviously adding to the burden in terms of time and cost.

To prevent this from happening, make sure there is a tight fit between the transfer paper and the substrate and that the ink is dry.

Not Vibrant

If your printed sublimation transfers are dull, this can either be normal or a problem.

In many cases, the pattern on the sublimation paper is dull. When it is transferred to the sublimation blank, the pattern becomes clear .

But if your pressed sublimation blank still has a dull image, it may caused by some aspects. First, You printed on the wrong side of the paper. Then,It is possible that you are not using sublimation ink. Lack of ICM profile and poor picture quality all could be the cause.

Transfer Lines On Apparel

Sublimation blanks that are soft like shirts, towels, linen, and neoprene do not need a heavy pressure in the heat press. The edges of the sublimation transfer paper can leave a line on your soft blanks from being pressed too heavily.

What Specific Solutions are there for these Problems?

Now, we have known some common problems in the transfer process. So, how can we avoid these problems?

Next, let’s talk about what points we need to pay attention to before and during transfer.

Before Printing

Control the Quality of Sublimation Paper

First, choose a suitable sublimation paper supplier, such as A-sub. Our company continuously optimizes product performance. There are also many sublimation papers to choose from. Each sublimation paper has its own advantages.

Secondly, the sublimation paper should be stored in a cool and dry environment to reduce the influence of air humidity on the paper. If you’re still worried, you can put the paper on the printer before transferring. The heat from the printer should help evaporate most of the moisture.

Pre-pressed Blank

Moisture is the enemy of sublimation. All fabrics have some type of moisture. So be sure to preload.

Identify the Components of Blank

If the polyester content of the blank is less than 30%, we should choose other transfer methods. Blindly using sublimation transfer printing will only waste resources.

When encountering soft white embryos, don’t press too hard.

Check Equipment

Make sure that the nozzles of the printer are not clogged. Check the sides of the printer for ink smudges. Make sure image rendering device are consistent so that no incorrect Output Color.

Make sure you have downloaded or used the latest version of the ICM profile provided by sublimation ink manufacturer.

Confirm Ink

The ink must be sublimation ink and sufficient. It is important to choose a reliable sublimation ink. The sublimation ink produced by our company has also been well received.

Precautions During Operation

It is ensured that the employees who operate the equipment have undergone rigorous training and are proficient in sublimation printing skills.

During the transfer process, different pressing methods are used according to different blank.

Make sure there is a tight fit between the transfer paper and the substrate and the ink is dry.

Use sublimation paper correctly. Avoid printing on the wrong side of this situation.

Conclusion

In fact, the problems encountered during transfer are inseparable from the quality of the transfer paper, the professionalism of the printing equipment and manual operations.

Choose the right sublimation paper and sublimation ink. Check equipment before transfer. Workers are proficient in operating skills. The probability of your transfer success will be very high.