Intro

If you are new to sublimation printing, please read this article. The whole article will give you a basic understanding of sublimation printing. This article revolves around a basic question of how sublimation printing works.

We need to understand what is sublimation printing, the consumables it needs and its operation steps. Even the problems that may arise in printing must be understood.

Next, we will lead you to understand sublimation printing in detail from these aspects.

Brief Introduction of sublimation printing

Sublimation printing is a transfer method that uses ink and heat to transfer a design onto a material or fabric.

Sublimation printing uses heat to fuse the ink and surface material or fabric, depending on the situation. The ink used in the sublimation process turns to gas when heated, then bonds with the textile and imprints it permanently on the fabric. The result is permanent and less prone to fading as the ink soaks into the material rather than simply laying on top like normal prints.

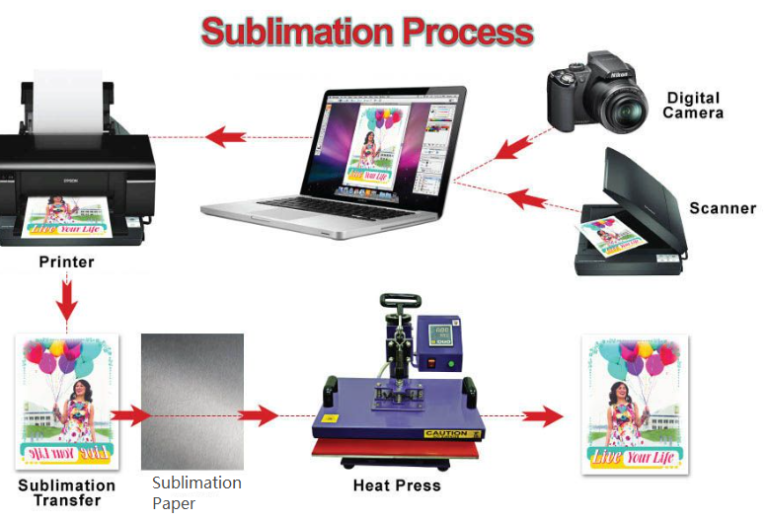

The process of sublimation printing

Sublimation printing is used to print on products made of or coated with polymer or polyester garments. In the garment section, 100% polyester garments are best suited for sublimation printing. The consumables required for sublimation printing mainly include sublimation paper, sublimation ink, and white embryo. In addition, it also requires equipment such as printers and heat presses.

The process of customers for sublimation printing is divided into the following three steps. First, artwork/designs are created on the product using product design software. Then, the design is sent to a sublimation printer and copied onto sublimation paper. Finally, the graphics are printed onto the product using a heat press machine.

It is important to note that sublimation printing uses inks made from solid dye particles. Initially, this ink was printed on transfer paper using a sublimation printer, where the ink solids were embedded in the paper. Finally, we put the transfer paper on the product and heat press it.

Possible problems and solutions of sublimation printing

Sublimation printing is used more and more in our daily life. There will inevitably be some problems during the transfer process. Such as banding, moisture issues, etc. These problems will more or less affect our final print quality.

Let’s discuss the common problems and solutions in the sublimation printing process.

Ghosting

Ghosting is when the print ends up with blurry images and shadow-like images. If the paper is displaced or not seated firmly against the heat press or the ink does not dry during pressing, the pattern will be ghosting.

When ghosting occurs, all the printing efforts of the manufacturer are in vain, obviously adding to the burden in terms of time and cost.

To prevent this from happening, make sure there is a tight fit between the transfer paper and the substrate and that the ink is dry.

Output Colors Are Incorrect.

Color mismatch issues are usually not the result of a flawed system, but rather the result of multiple image rendering devices involved in the process. Each image rendering device has a different color management method and range.

This problem requires us to adjust the print settings in time.

Wrong Blank

When you see blanks or lighter areas in the pressed sublimation, it may be due to uneven heat from the heat press or moisture on the sublimation blank.

Sublimation requires high temperatures to come out properly. Moisture prevents heat, so your design doesn’t transfer completely to your blank.

Faded Print

If you choose a blank that polyester fiber content is less than 30%, you will get a faded pattern after transferring. This is because the sublimation ink will only permanently transfer to the polyester portion of the fabric.

Too much time, too much temperature, or even too much pressure can make your print look faded.

If you want to know more about faded printing, you can choose to watch the video below by yourself.

Banding

When you print a sublimation paper, you may notice a visible blank line or area and lack of print, this is called banding.

Banding is the most common problem in all digital inkjet printing systems. This is generally caused by clogged print nozzles. Sometimes it may also be caused by running out of ink and so on.

I suggest that you check the nozzle of the printer every once in a while. At the same time, please remember to replenish ink in time.

Extra Ink

Sometimes, you’re pressing a design on a shirt and you have a small blotch off to the side.

Maybe your printer got a little smudge off to the side, and you didn’t even notice it. Then, you get that extra ink on your shirt unfortunately.

If you see extra ink on your print, you can cover it with heat-resistant tape before you press. By this way,the extra bit of ink doesn’t transfer onto your shirt. Remember any ink on that piece of paper is going to transfer to your shirt no matter how small it is.

In fact, the problems encountered during transfer are inseparable from the quality of the transfer paper, the professionalism of the printing equipment and manual operations. Even the way supplies are stored requires special attention.

Choose the right sublimation paper and sublimation ink. Check equipment before transfer. Workers are proficient in operating skills. The probability of your transfer success will be very high.

Finally, if you want to know more about sublimation printing, you can click the link below and choose the appropriate video or article to browse.

Video: https://www.youtube.com/@asubpaper/search?query=sublimation

Article: https://asub.com/blog

Conclusion

Simply put, sublimation printing is a transfer method that uses ink and heat to transfer a design onto a material or fabric.

Generally, the consumables required for sublimation printing mainly include sublimation paper, sublimation ink, and the blanks. In addition, it also requires equipment such as printers and heat press machine. The operation steps of sublimation printing are mainly divided into 3 steps, including design pattern, printing, heat transfer printing. Companies with little experience may have various problems at the beginning of sublimation printing, which can be solved by paying attention to details in sublimation printing and improving the quality.

I hope this article can help you.

Very well written article, kudos to author. Please visit us if you want more information.