Intro

The steps of sublimation printing are not complicated. However, there are actually a lot of mysteries inside. Today I want to talk to you about some points in the sublimation printing process.What should be paid attention to when sublimation printing?

When printing, pay attention to the print settings. Then focus on the time, pressure and temperature needed for the transfer. At the same time, I must also mention the importance of compatibility between sublimation paper and ink.

Next, I will elaborate on these points.

What should be paid attention to when sublimation printing?

I will answer the questions in four main aspects.

Check Print Settings

The settings of the printer is related to the paper size, material, pattern requirements and other factors.

First, you need to create a new canvas according to the paper size and pattern effect requirements.

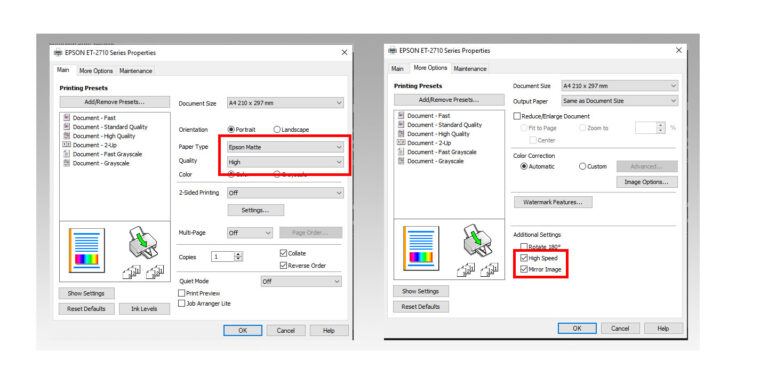

Next you have to choose the paper type, color mode. For example, if you are printing on sublimation paper, then you must select the corresponding paper type.

Most importantly, many sublimation papers on the market require mirror printing. This must not be forgotten.

The specific printing operation can be found in the video below.

Pressure of heat press

Pressure is also one of the important parameters of thermal sublimation transfer technology.

For example, if the pressure is too small, there will be a large gap between the fabric and the transfer paper, and the ink molecules will dissipate by colliding with a large amount of air. This will lead to poor results. Ink seepage, thick lines, and blurred patterns may all appear.

Excessive pressure can easily deform thick fabrics, resulting in a hard hand feeling.

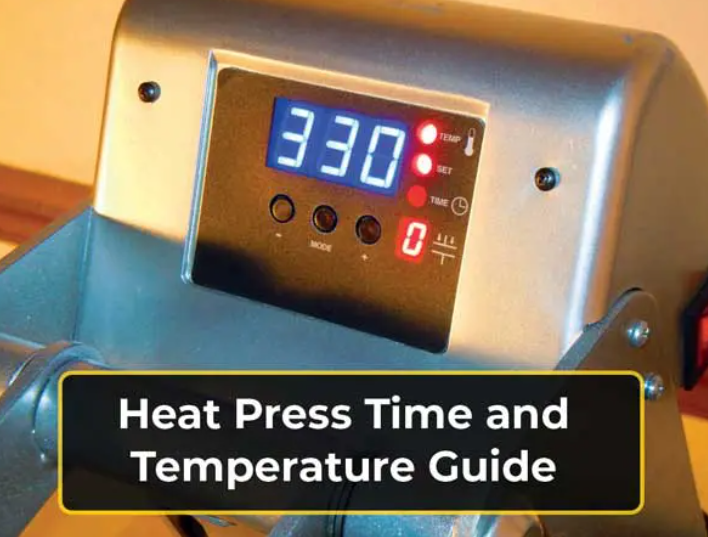

Heat press time and temperature of sublimation paper

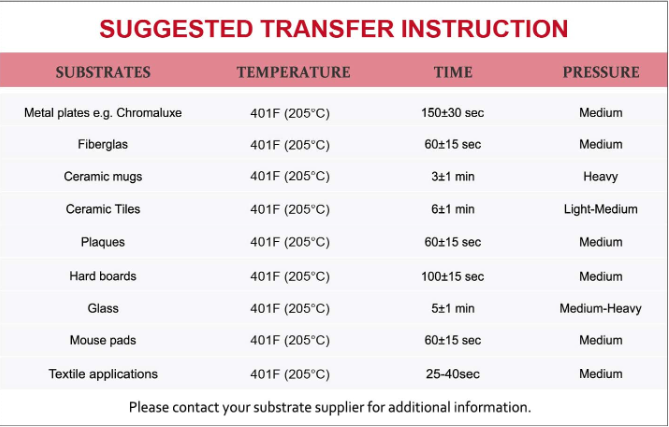

Temperature and time will vary based on sublimation blank.

Recommend checking the manufacturer’s info about the heating process for your sublimation blank.

Take A superior sublimation paper as an example

For best results we recommend to use a transfer temperature of 205℃。Using this temperature will enhance the transfer quality.e.g. color densities and line sharpness.

Depending on the material of the blanks, the time and pressure required for heat pressing are different.

In addition, there are 4 types of heat press machines on the market, you can choose according to your needs.

Small Heat Press

If you’re planning to sublimate on small items such as t-shirts and hats, mugs, plates and shoes, you can choose a small heat press.

Calendar Heat Press

These heat presses are large format presses. Users can cut and sew apparel pieces with the addition of table attachment to calendar unit.

They are built for flags, large exterior banners, and other large soft-signage applications, as well as day-to-day soft signage and fabric sublimation.

Flatbed Heat Press

Although flatbed heat press can only handle flat sheets of sublimation paper, it is versatile heat presses that can transfer heat to fabric as well as aluminum, cardboard, floor mats, and other unique media.

3D vacuum heat press

The 3D vacuum heat press is a compact tabletop machine that transfers heat to materials with curved edges or shapes. Sublimation blank and pre-processed objects such as smartphone cases, mugs, photo frames, sporting goods, buttons and other sublimation available for this device.

Material selection precautions

Matching ink and sublimation paper

The main consumables for sublimation printing are sublimation paper and ink. The first point to choose sublimation ink, because sublimation ink molecules are small and easy to volatilize. At the same time, we should not underestimate the compatibility of sublimation paper and ink, because it will affect the color of the final picture. The higher the compatibility of the paper and ink, the more beautiful the printed pattern.

How do we go about improving the compatibility of sublimation paper and ink? What we can do is to try to choose consumables under the same brand.

Types of sublimation paper

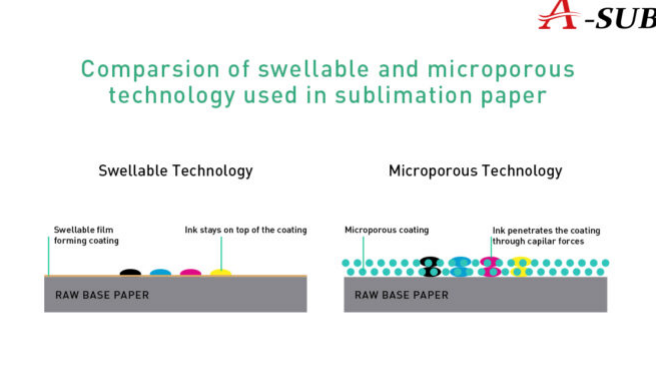

From a technical standpoint, there are two types of sublimation paper on the market. As I mentioned, good sublimation papers have similar features. Let’s analyze the difference between these two sublimation papers and how to make a choice.

Swellable Sublimation Paper is the First Generation

This sublimation paper is made by coating it with organic polymers, like gelatin. This coating swells up to surround the sublimation ink once the ink strikes the paper.

In layman’s terms, when the swellable sublimation paper is working, the ink is attached to its surface. So it’s not hard to figure out that it has excellent image finish and print durability.

However, swellable paper is more sensitive to contact with water and highly humid environments. As a result, the produced prints also require longer drying times.

This posed a problem as ink jet printers tended to print faster than the sublimation ink could dry. Consequently, another form of paper has gained prominence.

The Performance of Microporous Sublimation Paper is Better

Microporous coatings are alumina or silica in tiny, inorganic particles that create voids or cavities in the coating. The sublimation ink is then absorbed into these cavities by capillary action.

As a result, microporous papers have high resistance to moisture and humid conditions. That is to say, microporous papers help produce rapidly drying prints. It solves the problem of swellable papers.

Of course, in terms of transfer rate, warpage and other properties, microporous paper is also better.

From weight,Different grammages of sublimation paper are used for different purposes.

The weight is related to the paper itself and the amount of sublimation coating. Thicker coating ,more saturated sublimation paper can more effectively deal with the saturation of thick ink.

At the same time, the weight of the sublimation paper is related to the curl. We should often see different weights when purchasing sublimation paper. In the case of the same size of paper, the difference in weight is due to the difference in thickness.

we need to consider it according to the actual situation. If our pattern is simple and the color saturation is not high, we can choose a thinner sublimation paper. Otherwise, you need to choose a thicker one.

For example, if you use sublimation paper with a weight of 105 grams, it will curl when printing. Then you can change the sublimation paper of the same size with a weight of 120 grams, or even heavier sublimation paper.

If you are interested in the selection of materials, then the following articles can give you answers to your questions.

What Is The Standard For Good Sublimation Paper?

How To Import High-quality Sublimation Ink?

Conclusion

There are many factors that need to be taken into account in the sublimation transfer process. This article focuses on the print settings, the time and temperature of the heat press, and the choice of materials.

We should not only buy the right type of sublimation paper according to our needs, but also pay attention to the matching. Print settings and heat press time and temperature are always in accordance with the actual operating instructions.

In addition, If you want to know more about sublimation printing , you can click into the article link to get more content.

The article is informative, setting up the right temperature and material is very important. Visit us we also do the sublimation printing and more https://alwansilkscreen.com/

The article is informative, setting up the right temperature and material is very important. Visit us we also do the sublimation printing and more https://alwansilkscreen.com/