There are many guides on the web for choosing the sublimation paper, but the selection criteria are not uniform. People are often confused about what criteria to use when selecting the sublimation paper. This article will describe this in detail. We will analyze and summarize the common methods of choosing thermal sublimation paper on the market. After reading this article, we hope that you will have a more comprehensive understanding of what kind of sublimation paper to choose for production.

Brief Introduction to Sublimation Paper for Shirts

As one of the most popular printing papers, sublimation paper has been used in various fields. If you look closely, the technology of sublimation paper can be found in offices, shopping malls, and homes. It can be found everywhere in our daily life. Therefore, the market for sublimation paper is huge and full of potential. Sublimation paper allows you to easily master transferring to garments.

Types of Transfer Paper for Shirts

Before introducing the sublimation paper for shirts, I would like to show you more about the main transfer paper for shirts in the market. They are all famous in the market of shirt transfer. When compared with sublimation papers, they also have their shortcomings.

●T-shirt Transfer Paper

The T-shirt transfer paper is starting to fade out of the spotlight. It is mainly used to transfer fabric products containing a high amount of cotton or man-made fibers and less than 30% polyester fibers. It is very breathable. Thus, there are many children’s clothing or underwear fabrics that choose to use T-shirt transfer paper. T-shirt transfer paper is also available to DIY at home. It is easy to use and only works with a printer and an iron. On the other side, this also means that T-shirt transfer paper has a disadvantage, which is that it is not widely available. And compared to most products on the market, T-shirt transfer paper is not the cheapest.

●DTF Film

DTF film is a recently developed transfer paper. Compared to T-shirt transfer paper and sublimation paper, its main advantage is that there is no restriction on the use of fabrics. DTF film can be used on most fabrics regardless of the base color. And during the printing process, the top layer of DTF film is printed with white ink, thus preventing the base color of the fabric from covering the transfer pattern.

However, DTF film needs to work with a modified printer and powder shaker. These two machines are very expensive. If you don’t have a large order, you’d better not use DTF film. DTF film is more suitable for high-volume production.

●Sublimation Paper

Sublimation paper is the most common transfer paper on the market. It is easy to use and easy to learn. Both fabrics and hard substrates can be transferred through the sublimation paper. The events that need to be paid attention to are just that the polyester fiber content of the fabric must be more than 30% and the surface of the hard substrate must have a coating.

For clothing, the garments obtained by the sublimation transfer are breathable and do not lose color easily after rubbing and washing. It is the best choice for fabric transfer except for cotton and chemical fiber garments. Most importantly, the unit price of the transfer paper is very low, which can save a considerable amount of money for the manufacturer of the transferred garments.

Choosing the Right Sublimation Paper for Shirts

The choice of sublimation paper means that the polyester fiber content of the garment is more than 30%. Except this, we recommend you use the sublimation paper on the fabric with a light basic color. These are the fabrics that can be sublimated. However, do you know how to choose the right sublimation paper for the shirts? Please read on to learn more.

●Weight and Thickness of the Paper

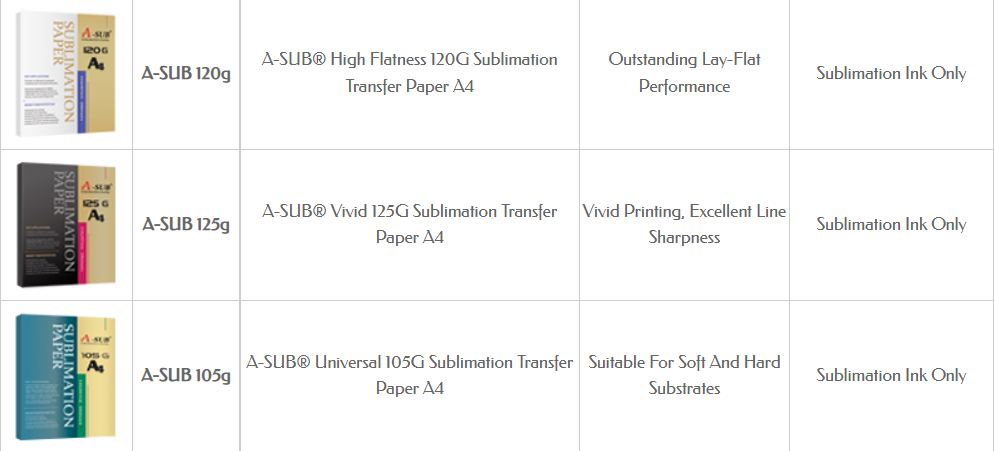

The numbers 105g, 120g, and 125g reflect the weight of the paper per square meter(in grams) (before cutting), after being cut into a size suitable for retail packaging.

For example:

8.5 * 11 size paper, the difference between the three options of 105g, 120g, and 125g. is the weight. And because the dimensions are exactly the same, the difference lies in the weight and thickness of the paper.

The change in thickness is related to the paper itself and the amount of sublimation coating. Thicker coating and more saturated sublimation paper can more effectively deal with the saturation of thick ink. The thinner sublimation paper is very suitable for your light-colored ink saturation needs.

●How to Judge If You are Using the Correct Sublimation Paper?

If your work is going well and your design is clear, then you must have the right paper. However, if any of the following problems occur, try to replace the paper as follows:

(1)My paper always curls-try to increase the weight: If you use 105g, increase to 120g, if you use 120g, increase to 125g. Also, it maybe means you need to pay attention to the storage of the paper. If there is no problem in the storage of the sublimation paper, just increase the weight of the sublimation paper.

(2)My paper always has wheel marks-go in the opposite direction: If you are using 105 grams, increase to 120 grams. If you are using 120 or 125 grams, please switch to 105 grams. If the problem persists, clean your printer thoroughly.

(3)Variable saturation design: If you often print a design that includes both light ink saturation and heavy ink saturation, please keep it in the middle of 120 grams. If you use 105g, the heavy part of the design may move, bleed or double-image.

(4)My hard/rigid blank is ghosting: The ink has nowhere to go, and there may be too much to deal with. Go to the lowest grammage.

(5)My T-shirt looks faded, but all the ink is transferred: The grammage has increased because it accepts more ink.

Tips and Techniques for Sublimating Shirts

Of course, you need to find the most adjustable printer and heat press to work with the sublimation paper you chose before learning more tips and techniques for sublimating shirts. We usually choose Epson and Sawgrass printers because of their wide availability in the process of transferring.

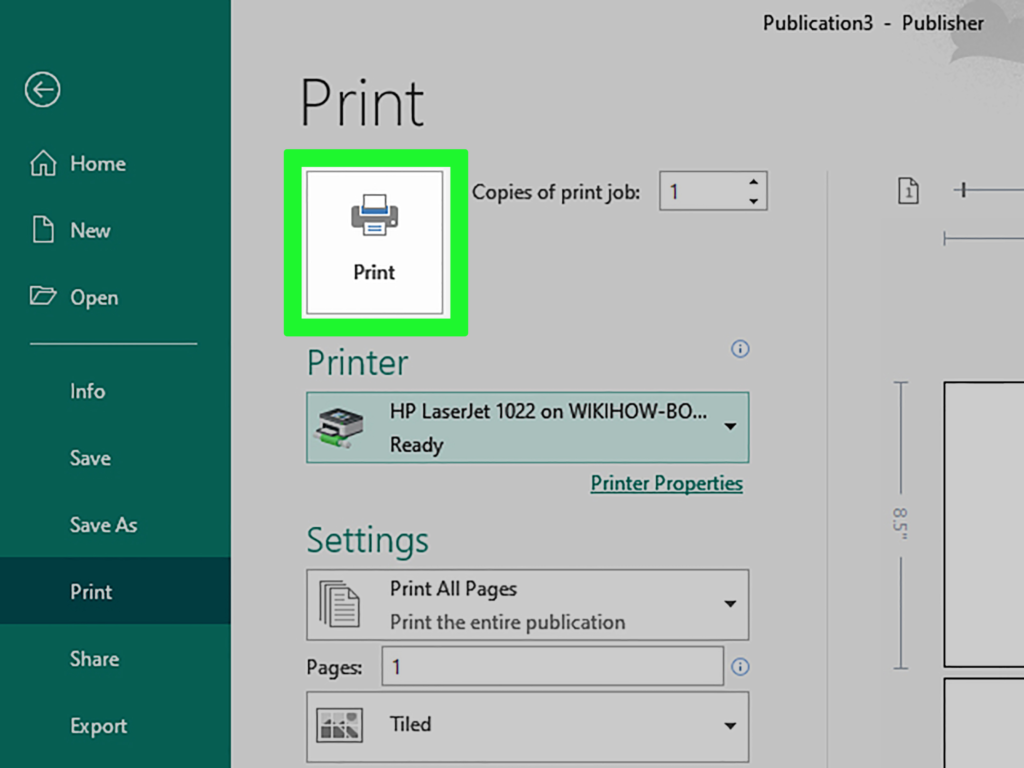

Firstly, when printing the pattern, pay attention to the pattern that needs to be set up for mirror printing. Secondly, before heat transfer printing, the heat press should be preheated and the fabric should be laid flat. Finally, after the heat press is finished, we need to wait for it to cool down before we can remove the paper.

Conclusion

Here is the ultimate guide to choosing the sublimation paper for shirts. The vital standard is the weight and thickness of the sublimation paper. Different types of sublimation paper are available for different kinds of fabrics. By the way, the type of printer maybe has an influence on the sublimation, too. As a result, we recommend that you get free samples of sublimation paper to try on your printer to find the best sublimation paper for you.

If you want to learn more about the other kinds of paper, welcome to click the page to check in. If you have any questions about this article or other kinds of paper, welcome to comment at the end. We are waiting for your reply and e-mail all the time. Thanks a lot.