Intro

Packaging labels play a crucial role in identifying, promoting and protecting products during transportation, handling and storage. Among the various factors that make packaging labels durable, water-resistance is becoming increasingly important. Why water proof labels are the top choice for durable packaging? What’s the benefits of using them?

Water proof labels ensure longevity and prevent damage to products. They also maintain the label’s appearance and protect important information.

This article will explain these questions in detail.

Introduction

A. Explanation of packaging labels and their importance

Package labels are essential pieces of information that appear on the packaging of products. These labels provide important information about the contents of the package, including nutritional information, ingredients, expiration dates, allergens and other important information. They are critical to informing consumers about the products they buy and use and to ensuring their safety.

Packaging labels also play an important role in regulatory compliance, helping to ensure that products meet government requirements and regulations. In addition, they can serve as a marketing tool, helping to differentiate products from competitors and communicate important brand messages.

Overall, packaging labels are essential for consumer safety and satisfaction, regulatory compliance, and effective marketing.

B. Why water proof labels are the top choice for durable packaging?

Durability is a critical factor for packaging labels, as they are responsible for carrying essential information about the product, including its name, ingredients, date of manufacture, expiration date, and other relevant details. It is essential that these labels remain intact and legible throughout the life of the product to ensure that customers have access to accurate information. In addition, packaging labels play an important role in brand recognition and marketing, so it is important that they remain attractive and visible.

One of the top choices for durable packaging labels is water proof labels. These labels are designed to withstand exposure to moisture, humidity, and other environmental factors that can damage or fade traditional paper labels. They are made from materials such as vinyl or polyester that are more resistant to water and other liquids, ensuring that the label remains intact and legible even when the product is exposed to moisture. In addition, water proof labels are more resistant to tearing, scratching, and fading, ensuring that the label remains attractive and legible throughout the life of the product.

Benefits of water proof labels

A. Protection from water damage

Waterproof labels are designed to resist water damage, making them ideal for use in environments where moisture is present. By using waterproof labels, companies can ensure that their products are protected from water damage, which can cause labels to become illegible or fall off. In addition, waterproof labels can be used on outdoor products or in wet environments, such as bathrooms or kitchens, where regular labels would not be suitable. By using waterproof labels, companies can ensure that their products remain visible and legible even in wet conditions.

B. Resistance to abrasion and chemicals

In addition to resisting water damage, waterproof labels are also resistant to abrasion and chemicals. This means that they can withstand exposure to harsh environments and chemicals without deteriorating or losing adhesion. For example, in the industrial sector, where chemicals and abrasive substances are commonly used, waterproof labels are essential to ensure that critical information such as safety warnings or operating instructions remain visible and legible. This resistance to abrasion and chemicals makes waterproof labels a reliable option for long-term use.

C. Long-lasting adhesion

Waterproof labels are designed to provide long-lasting adhesion, ensuring that they remain in place even when exposed to harsh conditions. This means that companies can rely on these labels to stay in place for the life of the product, reducing the need for frequent label replacement.

D. Versatility in various industries

Waterproof labels are versatile and can be used in various industries, including the food and beverage industry, healthcare, industrial and manufacturing sectors, and the outdoors. This versatility makes waterproof labels an excellent option for businesses that require labeling solutions for products used in diverse settings. For example, waterproof labels are ideal for food and beverage products that require refrigeration or freezing. Additionally, waterproof labels can be used in healthcare settings to ensure that medical equipment and instruments remain labeled and legible, reducing the risk of errors.

Applications of water proof labels

water proof labels have a wide range of applications in various industries. Here are some examples of their applications in specific industries:

A. Food and beverage industry

In the food and beverage industry, water proof labels are commonly used for product packaging and labeling. These labels help to ensure that important information such as the product name, ingredients, nutritional information, and expiry date remain visible and legible even in damp or wet conditions, such as in refrigerators or during transportation.

water proof labels are especially useful for packaging products that need to be stored or transported in wet or humid environments, such as canned goods, bottled beverages, and frozen foods. They help to prevent the labels from peeling off, smudging, or becoming unreadable due to moisture.

B. Medical and pharmaceutical industry

In the medical and pharmaceutical industry, water proof labels are essential for ensuring that important information about medications, medical devices, and other healthcare products remain visible and legible. These labels help to prevent damage from exposure to moisture, which can cause the ink to run, smudge, or fade.

water proof labels are especially important for products that need to be stored in damp or humid conditions, such as vaccines, blood products, and medical devices that are sterilized with water. These labels help to ensure that the information remains visible and legible throughout the product’s shelf life.

C. Personal care and cosmetics industry

In the personal care and cosmetics industry, water proof labels are used to ensure that product information remains visible and legible even in damp or wet conditions, such as in the shower or on a damp bathroom counter. These labels help to prevent the ink from smudging or fading due to moisture.

water proof labels are especially useful for products that are used in wet environments, such as shampoos, conditioners, and body washes. They help to ensure that the labels remain in good condition, which is important for maintaining brand identity and complying with labeling regulations.

D. Industrial and manufacturing industry

In the industrial and manufacturing industry, water proof labels are used for a variety of applications, such as identifying equipment, tracking inventory, and providing safety warnings. These labels help to ensure that important information remains visible and legible even in damp or wet conditions, such as in outdoor environments or on equipment that is regularly exposed to water.

water proof labels are especially useful for products that are exposed to harsh outdoor environments, such as machinery and vehicles used in agriculture or construction. They help to ensure that important information remains visible and legible, which is essential for maintaining safety and compliance with regulations.

Factors to consider when choosing water proof labels

water proof labels are an important consideration for businesses that need to label products or equipment that may be exposed to water or other liquids. When choosing water proof labels, there are several factors that should be taken into account:

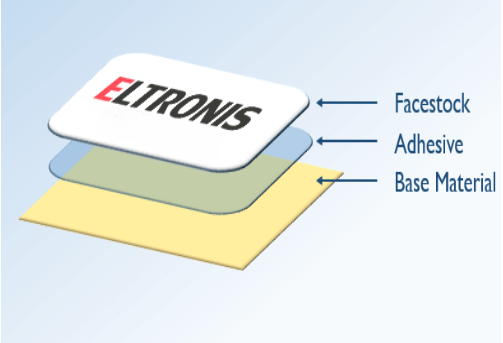

A. Materials and adhesives

The materials and adhesives used to make water proof labels are crucial to their durability and longevity.

According to the classification of surface materials, labels can be divided into two categories: paper labels and film labels. Generally speaking, film labels have better water resistance compared to paper labels. This is because paper labels are made of materials such as paper pulp or fiber, which tend to absorb water and can easily get damaged when exposed to moisture or water.

On the other hand, film labels are made of materials such as polyester, or vinyl, which are all highly resistant to water and moisture. These materials have low water absorption rates and do not easily dissolve or break down when exposed to water.

Therefore, film labels are typically used in applications where water resistance is critical, However, It’s important to note that the level of water resistance of a label can also depend on the specific material used and the manufacturing process. Additionally, some paper labels may be coated with a water-resistant layer or adhesive to enhance their water resistance.

There are generally three types of glue for labels, namely water glue, oil glue, and hot melt glue.Water-based glue is often used for paper labels and packaging. The effectiveness of the glue depends on the specific formulation of it and the conditions in which it is used. Some water-based glues can withstand exposure to water for extended periods, while others may start to break down or lose their adhesion after just a short time in contact with water.

Oil-based glues are generally less water-resistant than water-based glues. They are often used for labels that will not be exposed to water, such as those on metal or plastic containers. If oil-based glue is used on labels that will be exposed to water, it can start to break down or lose its adhesion fairly quickly. Therefore, oil-based glue is not a good choice for labels that need to be water-resistant.

Hot melt glue is a type of thermoplastic adhesive that is melted and then applied to a surface. It sets quickly and forms a strong bond, making it a popular choice for many types of labels. Hot melt glue can provide good water resistance.

Overall, when it comes to water resistance, water-based glue and hot melt glue are generally the best choices for labels that will be exposed to water. Oil-based glue is not recommended for labels that need to be water-resistant. It is important to choose the right type of glue for the specific application and conditions to ensure that the label will provide the necessary water resistance.

Most A-sub labels are Vinyl labels. Of course, there are also some paper labels. Moreover, the glue used in the A-sub label is all water glue and hot melt glue, both of which are waterproof. What’s more worth mentioning is that there are many types of A-sub labels, which can meet many different needs. If you have a need, you might as well come to find out.

B. Label placement and environment

The placement of the label and the environment in which it will be used are also important factors to consider. Labels placed on products or equipment that will be exposed to water or other liquids should be designed to withstand the specific environment. For example, labels used in marine environments may need to withstand exposure to saltwater, while labels used in industrial settings may need to withstand exposure to oil and chemicals. In addition, the label placement should be considered, as labels that are placed in areas where they are likely to come into contact with water or other liquids will need to be more durable than those placed in dry areas.

C. Compliance with regulatory requirements

Finally, it’s important to ensure that water proof labels comply with any regulatory requirements that may apply. For example, food products may require labels that are compliant with FDA regulations, while hazardous materials may require labels that comply with OSHA regulations. Compliance with regulatory requirements is essential to ensure that the label is legally valid and can be used without risk of liability.

In summary, when choosing water proof labels, it’s important to consider the materials and adhesives used, design, label placement and environment, and compliance with regulatory requirements. By taking these factors into account, businesses can choose water proof labels that are durable, effective, and compliant with any relevant regulations.

Difference between water proof label and water resistant label

Water proof labels are designed to withstand immersion in water without coming off or being damaged. These labels are usually made of materials that are specifically designed to resist water, such as vinyl or polyester, and are often used in applications where the label needs to remain legible and intact even when exposed to water for extended periods of time. Examples of waterproof labels include labels used on products that are stored in refrigerators or freezers, labels used on outdoor equipment or gear, and labels used on products that are shipped or stored in wet environments.

water resistant labels, on the other hand, are designed to resist water to some degree, but are not completely waterproof. These labels may be made of materials such as paper, and are often coated with a water proof material to help prevent them from smudging or smearing when exposed to water. water resistant labels are often used in applications where the label may be exposed to water or moisture, but does not need to withstand complete immersion, such as labeling products that are used in damp environments, or labeling products that are used outdoors but not directly exposed to water.

In summary, waterproof labels are designed to completely resist water and remain legible and intact even when fully submerged, while water resistant labels are designed to resist water to some degree but may not remain completely legible or intact when exposed to prolonged or heavy moisture. You can choose wisely according to your needs.

Conclusion

In conclusion, packaging labels are an essential part of any product’s packaging as they provide important information to consumers and also serve as a branding tool for businesses. Durability is a crucial factor to consider when choosing packaging labels, as labels that can withstand harsh conditions ensure that the information remains legible and the branding stays intact throughout the product’s life cycle.

Among the options available, water proof labels are the top choice for durable packaging due to their numerous benefits. These labels offer protection from water damage, resistance to abrasion and chemicals, long-lasting adhesion, and versatility in various industries.

water proof labels find applications in various industries, including food and beverage, medical and pharmaceutical, personal care and cosmetics, and industrial and manufacturing. Each industry has specific labeling requirements, and businesses must consider factors such as materials and adhesives, design and printing options, label placement, and environment when choosing water proof labels.

It is important to note that water proof labels are different from water resistant labels. While water resist labels offer protection against water to some extent, water proof labels provide complete protection and are suitable for products that will be completely submerged in water.

In generally, choosing water proof labels for durable packaging is a smart choice that businesses should consider. Careful consideration of the factors discussed will ensure that the labels meet the specific needs of the industry and comply with regulatory requirements.