At present, the transfer paper used for T-shirt transfer is mainly divided into two types: sublimation paper and T-shirt transfer paper. What is the difference in the composition of the two transfer papers?

From a structural point of view, Sublimation Paper is paper-like, and the other is a film-like transfer paper. Their composition is related to their transfer characteristics.

The rest of this article will explain a few topics related to this question in great detail. What is the difference in the composition? Why do they need different composition? What are their transfer principle?

What are the differences in composition?

As i mentioned, Sublimation Paper is paper-like, and T-shirt transfer paper is a film-like transfer paper. Now, let’s talk about this question in detail.

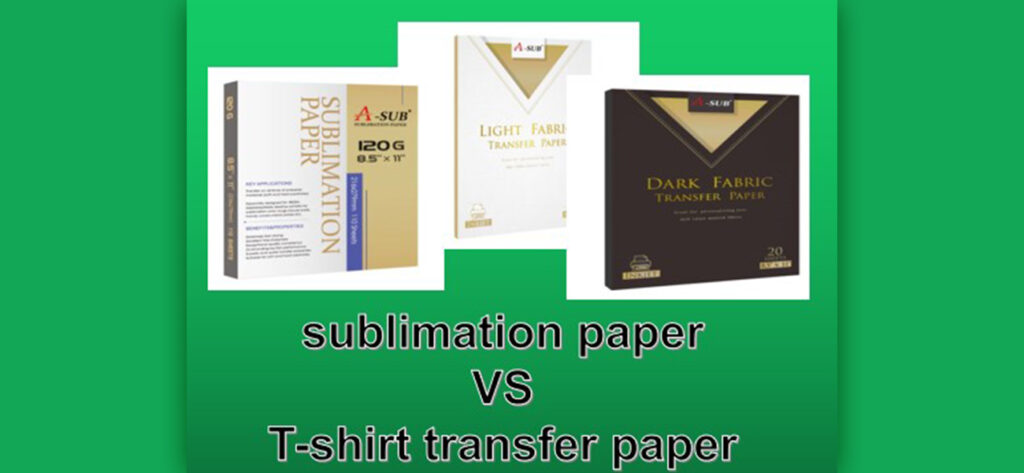

The composition of sublimation paper

The composition of sublimation paper has two parts. It is based on the normal based paper. And then making a special coating on it so that under the heat transfer, the patterns and be transferred on to the surface you want.

The thick coating of sublimation paper has a microporous structure that acts as a perfect receiver for sublimation inks. This high breathability of unique composition enables the transfer paper to absorb and store sublimation ink as quickly and accurately as a sponge.

It is worth mentioned that our company has developed a microporous multi-layer sublimation paper on this basis. This sublimation paper has improved in various properties.

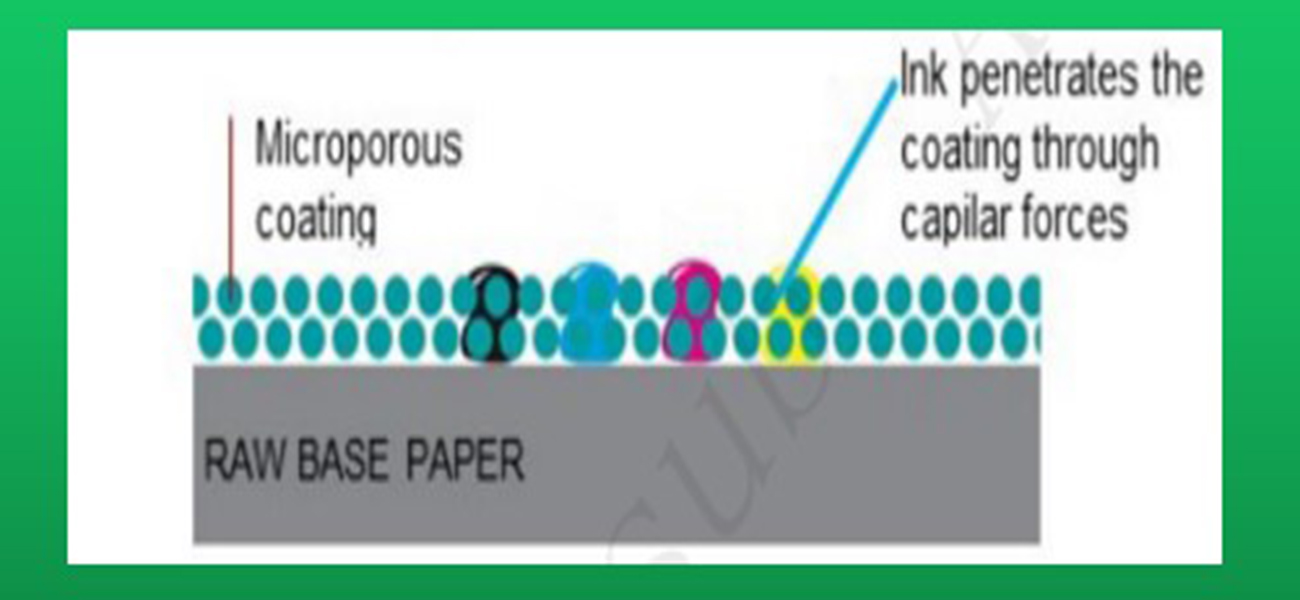

The composition of t-shirt transfer paper

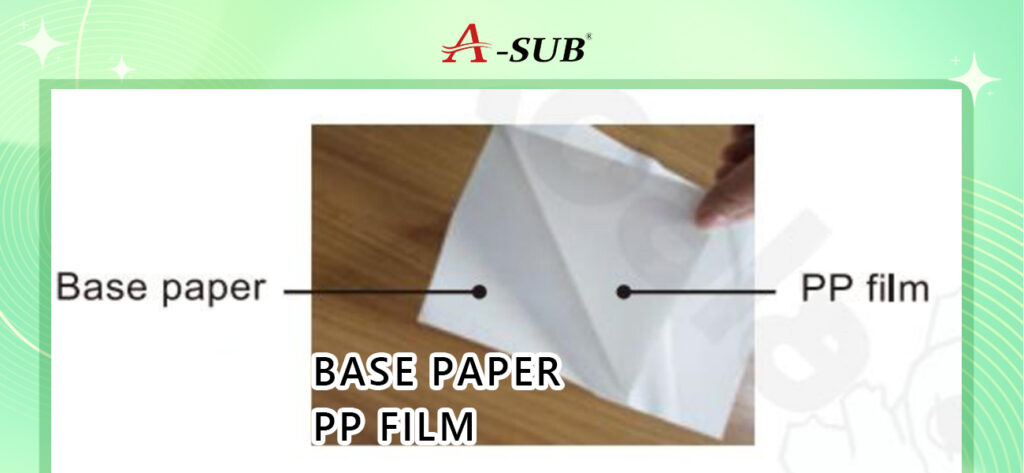

The t-shirt transfer paper has three layers, including base paper, ink absorption layer, and polypropylene (PP) film.

The base paper, or layer, serves as the foundation of the printing paper. It adds stability to the overall structure of the transfer paper.

The printed designs appear on the paper with the help of the ink absorption layer. This layer holds the printing ink before transferring the design to your fabric.

The PP film is a transparent layer on the paper that serves as the glue layer. This film allows the design to transfer and stick to the fabric properly.

There are different products suitable for inkjet and laser printers on the market. Our company mainly produces

inkjet pure cotton T-shirt transfer paper.

Why do they need different composition?

The different compositions of sublimation paper and T-shirt transfer paper are not created out of thin air. Their composition is related to their transfer principle and applications.

Different products require different transfer papers

Sublimation paper isn’t just for T-shirt transfers. Sublimation paper can realistically transfer portraits, landscapes, text, etc. to non-pure cotton fabrics, cups, porcelains, etc. It has applications in home improvement, clothing, promotional posters, etc.

T-shirt transfer paper is mainly used for pure cotton fabrics. Depending on the color of the T-shirt, light-colored T-shirt transfer paper and dark-colored T-shirt transfer paper can be used.

Different transfer principles have different requirements for transfer paper.

Sublimation paper has strong ink absorption capacity. T-shirt transfer paper has a thin layer of film. These are inseparable from the transfer principle.

Sublimation paper

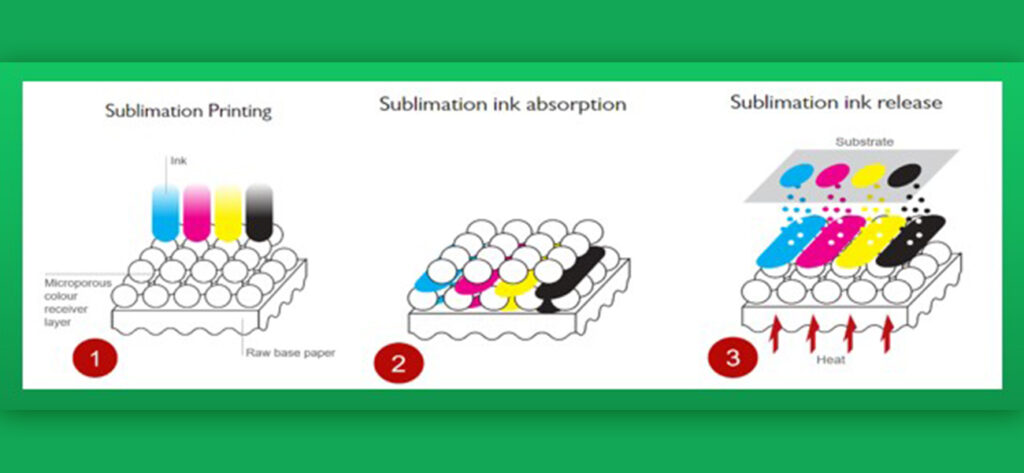

Firstly,Print on the A-sub Sublimation paper with sublimation ink.

Then, the microporous colour receiver layer quickly absorbs huge amounts of ink. This results in the fastest drying of prints, allowing users to immediately start subsequent production steps and achieve high optical density.

During the transfer process, the stored ink in the A-sub coating is activated earlier by the applied heat compared to swellable coatings . This results in quicker transfer times.

The ink is then released exactly where it has been printed for perfect line definition and detail reproduction.

T-shirt Transfer Paper

The color is absorbed and fixed by the ink-absorbing layer, and then the ink-absorbing layer is attached to the transfer medium through the adhesive layer.

The ink absorption layer receives ink without fading, thereby holding the design image. Then, the glue layer facilitates the transfer and attachment of the ink absorption layer to the selected material.

What is the difference between the transfer effect of sublimation paper and transfer paper?

Touch of patterns

Since there is a thin film in the composition of T-shirt transfer paper, the transferred pattern is tactile. The sublimation paper relies on the sublimation of the ink to be absorbed on the fabric, so the transferred pattern is not tactile.

Preservation of patterns

Sublimation transfer printing images are colorful and rich, and its effect is comparable to that of printing.

Sublimation transfer printing is to make the sublimation ink sublime and penetrate into the object at high temperature.

After sublimation, a bright color image is formed. Therefore, sublimation transfer products are durable and the image will not fall off, crack and fade.

As I mentioned, the pattern of T-shirt transfer paper is fixed to the surface of the fabric by an adhesive layer, so its preservation is not very good. It is not recommended to scrub the pattern part vigorously when cleaning.

Conclusion

In general, sublimation paper and T-shirt paper have different compositions and even the properties of the paper , because their different characteristics and transfer principle. They are applied to different items, each with advantages and disadvantages.