Intro

The DTF PET film is different from sublimation paper, T-shirt transfer paper and water slide decal paper. As a result, its method of application is also different from other kinds of transfer paper. This article is written to introduce the process of DTF printing and solutions to many common problems.

What is DTF PET Film?

DTF PET film is a brand new kind of transfer paper. Compared with the other kinds of transfer paper, it needs different ink, printer. Moreover, it needs DTF powder to complete the transfer. Seeing the article here, some of you may think DTF PET film is complicated and time consuming. But the truth is just the opposite. During the production process, DTF PET film is printed and transferred very quickly. Most importantly, it is very inexpensive and the transfer results are stunning.

What Do We Need to Do DTF Printing & Transferring?

The next section is an introduction to the materials and equipment that are necessary for DTF transfer. Before that, I would like to add a bit of information. Typically, we produce low volume products with DTF transfer through equipment such as ovens. However, for factory production lines, we recommend you to use Modified Printer&Powder Shaker.

●DTF PET Film

DTF PET film is the main material for DTF transfer. It has stable quality and low price. The transfer effect is also more vivid and outstanding. As a new kind of transfer paper, it will bring you a new experience like never before.

●DTF Ink

DTF ink is more concentrated than regular ink. Therefore, we need to modify the print head of the printer. With a high concentration of ink and a more suitable print head, you can print vivid enough patterns. What’s more, DTF ink’s biggest difference from the other kinds of ink is its white ink. Special white ink is used as the base color of the pattern. This can make the images have no chromatic aberration. The ink will hardly sublimate and is not sensitive to solvents. This means the DTF ink has high color fastness.

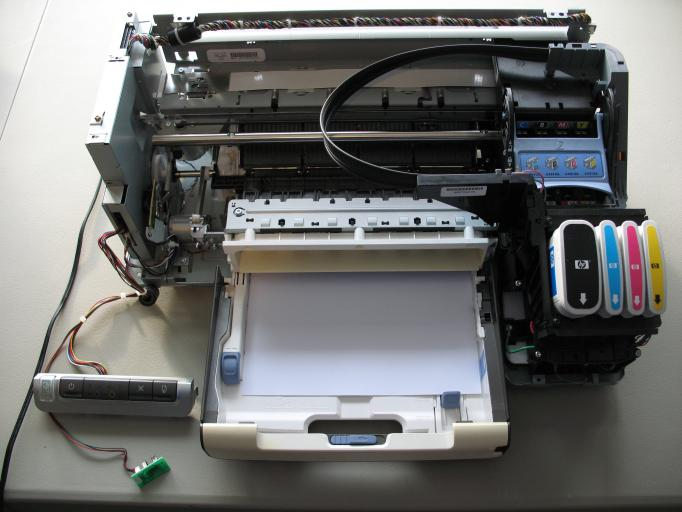

●Modified Printer

This DTF printer is easy to use on desktop and is also suitable for small manufacturers. This desktop DTF printer should be used with an oven and heat press. It is also easy to move around during the printing process. Before using a desktop DTF printer, the nozzles of the printer must be adjusted. Otherwise, DTF ink cannot be used in large quantities. We usually buy Epson printers because of the way they print. The way Epson printers print does not change the structure of the DTF ink molecules. The only disadvantage is that the whole printing and transfer process is more complicated. It requires more human resources and more time, which reduces productivity.

If we use the combination of powder shaker and modified printer, we will not have to worry about the above problems. The combination of these two machines can save labor and time costs to the maximum extent.

●DTF Powder

DTF powder is an important material in the process of transferring. It looks like white powder. We usually use it right after printing the film. If you don’t use the powder right after printing the film, the powder cannot cover the film well. Don’t neglect the function of DTF powder in the process of transferring.

There are two methods to use DTF powder, manual shaking and machine shaking. There is almost no difference between the effects of these two methods. But, these two methods can influence your efficiency and cost in a particular situation.

●Oven/Powder Shaker

The oven is usually used in the small office. It means complicated process and more manual work. On the other side, if you use powder shaker with the modified printer, you can finish the printing and powder shaking easily in one stop to save more human power and time. In the same time, you must spend enough money to purchase the machine and make sure that the machine is placed in a large enough space.

●Heat Press

The heat press should be preheated to 160℃-170℃. Then we can tile the substrates with the film and heat them for 10~20 seconds. The DTF film can be peeled whether it is cold or not. However, in my opinion, cold tearing would be safer if the conditions are right.

The Process of DTF Printing & Transferring

First of all, we need to prepare all the materials and machines mentioned above. Before printing the pattern, we should modify the nozzles of the printer. The modified nozzle will ensure sufficient ink output. After printing, the powder shaker will help us to shake and heat the powder.

Finally, cut it to the right size and heat transfer the image for 10-20 seconds with the heat press. Pre-heating the heat press to 160°C - 170°C can help the image transfer better to the substrate. In addition, DTF films can be peeled at both high and low temperatures. However, we prefer to peel them cold.

Frequently Asked Questions & Answers

Although DTF film is easy to use. Many people still have many problems in the process of DTF printing.

●Is DTF PET film eco-friendly? Can I reuse it?

Absolutely not. The DTF PET film has a layer film on the cover. This layer of film can not be use twice. If you want to get the most out of DTF PET film, you can prepare the design for printing in advance. This will minimize the waste of DTF PET film after cutting. This is environmentally friendly.

●Is there a requirement for the brand and model of desktop printer?

Yes. We recommend you to buy Epson or Sawgrass printers to do desktop DTF instead of the other brands of printers like HP and Canon. The HP and Canon printers are hot foam printers. Hot foaming is a high-temperature and high-pressure printing technology that causes the ink to bubble onto the paper by heating the nozzle. In the period, the DTF ink will produce chemical reaction. And then, the colors of the ink are not as bright as before. What’s more, the high temperature and high pressure will break the nozzle of the printer and reduce its service life.