The sublimation ink is based on the principle that the dispersed material is volatile, and the transferred pattern is vivid in color, clear in image, and can be stored permanently. At the same time, it is very suitable for the market needs of personalized development and the requirements of environmental protection. In the face of the dazzling array of products on the market, how do I choose the sublimation ink?

First of all, we need to understand the difference between sublimation ink and other inks, that is, what characteristics it needs to have. Then compare the existing sublimation inks on the market and select the most cost-effective sublimation ink.

The rest of this article will explain a few topics related to this question in great detail. What is the best sublimation ink? What are the characteristics of high-quality sublimation ink? Why use high quality sublimation inks?

What are the characteristics of high-quality sublimation ink?

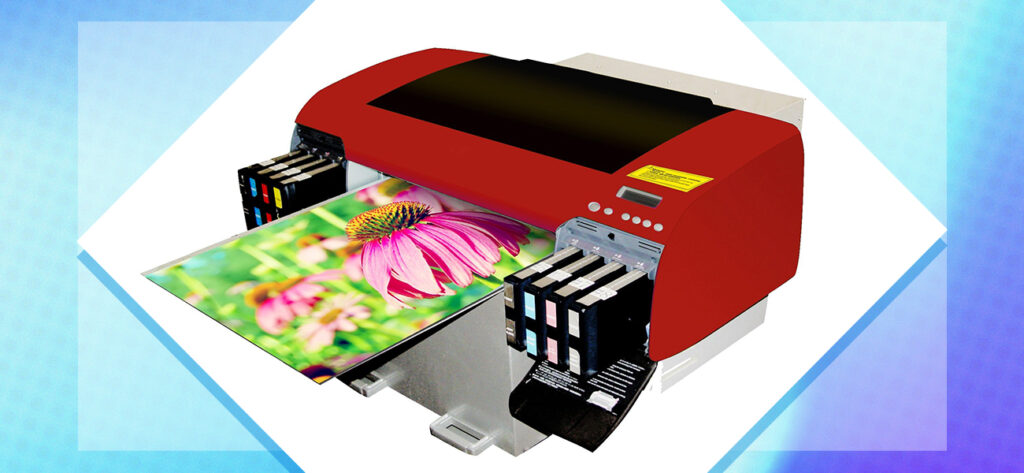

Dye-sublimation ink is to make low-energy, easy-to-sublime disperse dyes into digital printing inks, which are printed on sublimation paper. By heating, images can be transferred on porcelain, metal, chemical fiber cloth and other materials in the shortest time.

According to the production principle of sublimation ink, it is not difficult to know the characteristics of excellent sublimation ink.

High quality of raw material

High-quality raw materials are an important guarantee for ink. The price of raw materials is different. When considering the cost of ink, the quality of the ink should also be considered.

Ink is pigment particles uniformly distributed in organic solvent system of organic paint. For some poor inks, the particle suspension system inside will be very unstable because of her excessive pursuit of cheapness in the selection of raw materials.

With the change of temperature, the particles will appear layered and precipitated. The ink output is unstable and the nozzle is damaged.

Compatibility

In the selection of sublimation ink, try to choose the ink that suits your machine. The requirements of different nozzle inks may be different. One type of ink does not fit all digital printer models, and not all sublimation inks fit a printing press. Therefore, when choosing ink, try to choose a lightfast type.

Great color saturation

One of the advantages of thermal transfer technology is that the transferred patterns have high color saturation, clear patterns and rich layers. So good sublimation ink must have high color saturation.

High Color transfer rate

The color transfer rate is also important, which is the key to whether you can print a pattern with rich colors. It is also a guarantee of patterns with a sense of design.

Durability

Because the ink is sublimated by heat at high temperature, it penetrates into the surface of the medium and forms an image after sublimation.

Therefore, the sublimation ink will not form a film on the surface of the medium, and the image will not fall off or crack, and it has strong light resistance and will not fade for a long time.

Therefore, high-quality sublimation ink has strong penetration and is not easy to fade. In other words, durability is high.

High-quality sublimation inks should have these properties. For example, the Sublimation ink produced by our company prints smoothly, without clogging, and without oblique jet. Wide color gamut, high color saturation, and good line sharpness. Provides high transfer rates for printing in vivid colors. Scratch-resistant, long-lasting colorfast. And it’s sunfast and washable.

What are the benefits of choosing a high-quality sublimation ink?

Choosing high-quality sublimation ink not only brings high-quality transfer products, but also brings convenience to workers. The pollution to the environment is not large.

convenient

High-quality sublimation ink does not need to clean the nozzle during printing, just wipe it frequently. In this way, the efficiency and quality will be greatly improved, and more ink can be saved.

Beautiful images

The image is exquisite with bright colors , and its effect is comparable to that of printing. This can improve the market competitiveness of distributor and win more customers.

Environmental friendly

Good transfer inks are often made with disperse dyes. Disperse dyes are widely used in textile printing and dyeing due to their saturated colors and good weather resistance, and are still one of the main raw materials in the printing and dyeing industry.

The traditional textile printing and dyeing industry has serious environmental pollution problems in the process of dyeing with disperse pigments, and it is not suitable for small batch production.

Conclude

The best sublimation ink is selected according to the equipment you actually use and your needs.

Of course they all share common features, such as high durability, high color transfer rates, and more.

There are other benefits to using high-quality sublimation inks, too. It can greatly improve the work efficiency of workers, save ink, and be environmentally friendly.