The Asub-GL series is a high transfer rate, quick-drying product. It is the latest achievement of A-sub series products.

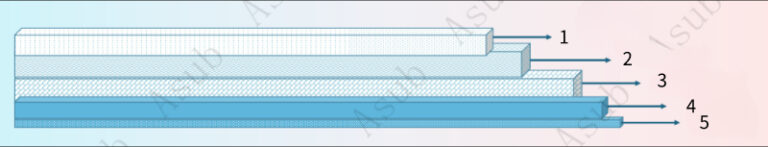

The Structure of the Asub-GL Sublimation Paper

Compared with the fast-drying series, it has a faster drying speed, more vivid colors, and more realistic images. At the same time, it offers better reproduction, higher definition and resolution, and better curl resistance. Besides, it is adaptable to different application environments and has low residual characteristics.

It is more adaptable and suitable for various printing methods. It is also ideal for printing in various printing modes and under various printing ink volume conditions. It presents more exquisite results under high ink volume and high precision printing conditions. Compared with similar products in the international market, the printing drying speed is faster and the residue is less. It is also impervious to printing.

As shown in the picture, the structure of the Asub-GL divides into 5 layers. Every layer has its unique function. From top to bottom, they are surface layer1, ink-absorbing structural layer2, water-absorbing separating layer3, the base material4, and anti-curl layer5.

Firstly, a surface layer means that a thin coating is made on the surface. This makes the paper surface smooth and fine without affecting the penetration of the ink into the absorbent layer. At the same time, it balances the front-to-back stretch ratio of the paper.

Secondly, as the name implies, the ink-absorbing structural layer is the structure that absorbs ink. On this layer of structure, we apply a special technology. This makes the use of sublimation paper easier and faster and high quality.

Thirdly, the function of the water-absorbing separation layer is to prevent water from the ink from entering the paper base so that back-transparency and back-bleeding can occur.

Fourthly, the base material is the presence that carries the other layers of the structure. And finally, the fifth layer is the anti-curl layer. We rely on it to prevent the thermal sublimation paper from curling and deforming. This ensures that the thermal sublimation process proceeds smoothly.

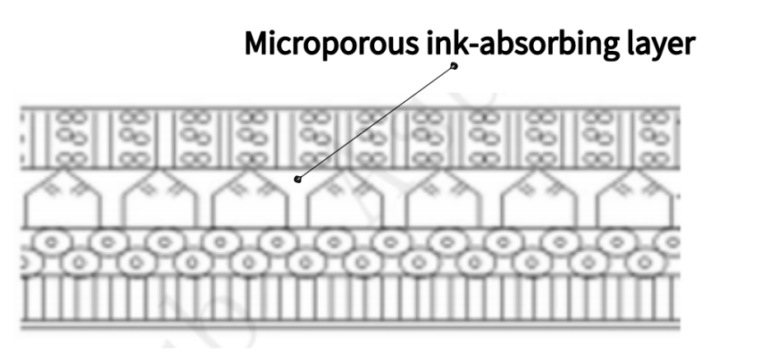

The Microporous Multilayer Technology

After learning more about the structure of the sublimation paper, you must be curious about the unique technology used in Asub-GL. Next, let us take you to dive in.

The unique technology Asub-GL used is called microporous multilayer technology. The microporous ink-absorbing coating will wet and swell and shrink the microporosity of the coating after ink absorption and drying respectively. This causes them to close and open accordingly. Then, fast drying and transfer of the ink are achieved.

After experimental measurement, the transfer rate can reach more than 95%. The fastest drying time of the printed paper surface can reach 20 seconds. The resulting product can absorb up to 300% of the ink volume of the sublimation ink surface image without swimming ink, the pile of ink, unclear images, and other phenomena. The amount of ink used to print sublimation paper is generally 180%.

The creation of this technology has made thermal sublimation printing easier and faster. At the same time, it also improves the image quality of the final product.

Comparison with other technologies

To more clearly highlight its technological advancement, we compared it with other early technology products.

● Swellable Technology

The swellable sublimation paper has two layers, the base material, and the swellable film-forming coating. The ink stays on the top of the coating. Compared to the other kinds of paper, its speed of drying and rigid substrates are not very good.

● Shortcomings

- Slow drying speed

- Mediocre line sharpness

- Low-quality hard substrates

- Low ink holding capacity

- Bad weather resistance

● Microporous Technology

Compared to the swellable sublimation paper, the sublimation paper using microporous technology has a lot of improvements. The ink penetrates the coating through capillary forces instead of being on the top of the coating. It has a very quick drying speed and excellent line sharpness. The dusting is at a medium level. When compared to the paper with microporous multilayer technology, it is not excellent enough anymore.

● Shortcomings

- Lower ink holding capacity

- Slower drying speed

- Bad weather resistance

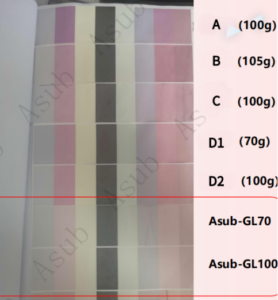

Comparison with other sublimation papers

We also compared this product with several popular ones on the market for experiments. We will prove the high quality of Asub-GL again with experimental data.

● Transfer Residue

To detect the transfer residue, we used INKTEC ink and an Epson L805 printer. The transfer condition is 40 seconds at 210°C. Product A to D2 is respectively from different areas. The result showed that Asub-GL has fewer residuals and obvious advantages. We also found that it has an excellent anti-color transmission effect than other products.

● Clarity

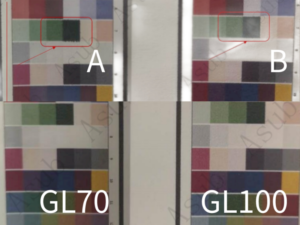

We prepared Epson 6280 printer and Epson ink to complete this experiment. A and B are the other brands’ products. The circled area occurred burrs and ink bleeding. At the same time, the area on Asub-GL70 & GL100 had smooth lines with no burrs or ink bleeding.

● Transfer Rate

During the transfer, we compared the transfer time of these kinds of sublimation paper at 210°C. Asub-GL series has an excellent transfer rate and the transfer time can be as fast as 30 seconds. The transfer time of other brands’ products took at least 40 seconds.

● Drying Speed

The high speed of drying is mainly attributed to the microporous multilayer technology. This technology makes the ink dry at once after reaching the coating. The Asub-GL120 sublimation paper can even dry in 20 seconds.

Summary

In summary, this is why the Asub-GL sublimation paper is of so high quality. The microporous multilayer technology has improved the products greatly. All indicators are far better than those of similar products. It has a fast drying speed, an extremely high transfer rate, vivid and clear colors, and very little transfer residue. The data and image comparisons above are proof of its high quality.

By the way, it has better cost performance than the A-sub sublimation paper. Importing Asub-GL will not only bring you a higher quality experience but also save your production costs. Thus, the Asub-GL sublimation paper is your first choice. If you have other related questions, welcome to comment to contact us. We will provide you with the best service.